At this year’s Emerging Textiles Conference, Dr. Andre West presented a compelling argument for the future potential of hemp as a sustainable alternative for industrial textiles, which he believes is at a watershed moment. Dr West is director of the Zeis Textiles Extension, North Carolina State University (NC State), where the research extends from the crop to textile processing. This affords a unique perspective in helping to identify the quality of fiber and the optimization of growing conditions best suited for yarn manufacture.

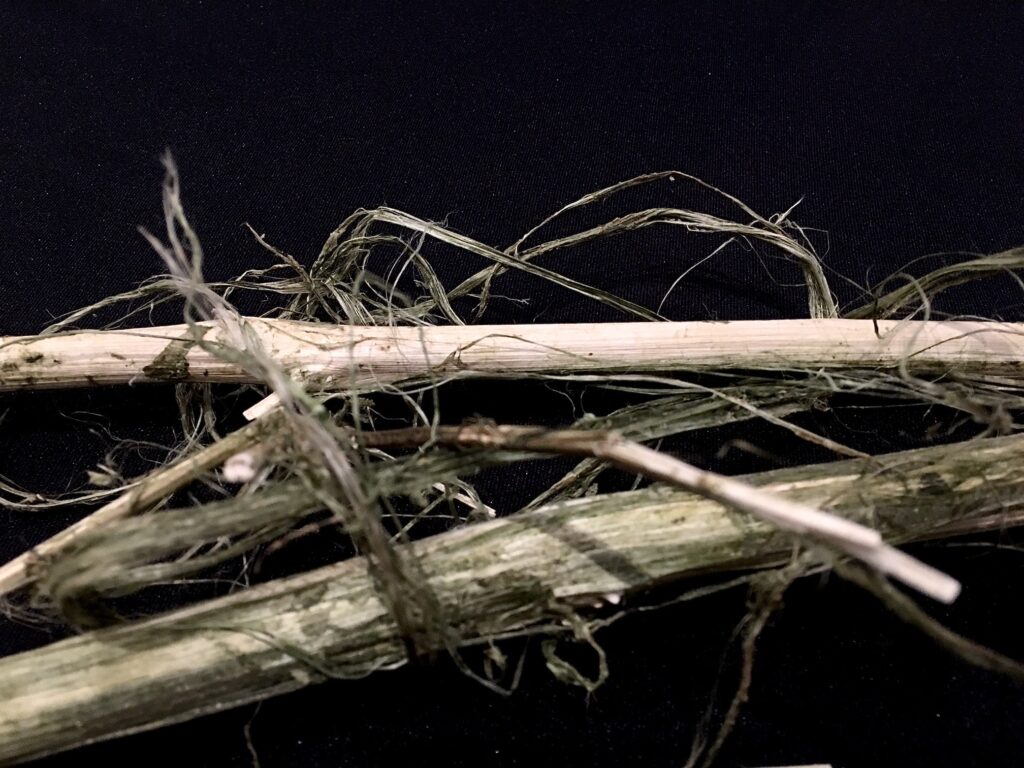

Hemp is part of the bast fiber family whereby the fiber-producing part of the plant is comprised of strands surrounding the woody core stem and running its length. This latter point has led to research into finding the best height to harvest the crop. Unlike crops such as cotton, there is no fixed time to harvest. The crop has many advantages, as it’s quick to grow, needs little water, is naturally repellent to many insects, and it has deep roots which helps to reduce soil loss and erosion.

The benefits of hemp have long been known. Dr. West told attendees that England’s King Henry VIII fined his subjects if they failed to grow a specified amount each year. Funding is in place to support research for the first phase with much of the work centered around efficiencies and data collection in growing the crop, coupled with spinning and blend exploration and testing. Engaging with manufacturers will be the next challenge.

Attending in the audience was Guy Carpenter from the Industrial Hemp Commission who contributed the observation that “hemp wears in not out,” meaning that the fabric gets softer with washing and wear.

Dr. Marie O’Mahony is an industry consultant, author and academic. She can be reached at marie.consultant@gmail.com.

TEXTILES.ORG

TEXTILES.ORG