Electrically conductive “smart fabrics” have many potential applications, but their specialized fibers typically aren’t as soft and flexible as those made of regular materials. An experimental new two-faced fiber, however, is both flexible and conductive.

Developed by a team of scientists at Washington State University, the fiber is made of two substances: an existing conductive synthetic polymer known as polyaniline and cotton cellulose obtained from recycled T-shirts. The polyaniline is combined with the cotton cellulose because it’s too brittle to be formed into usable fibers on its own.

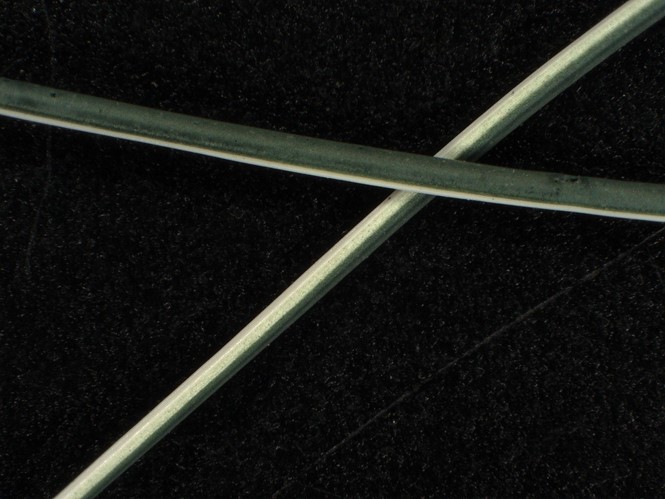

But the two materials aren’t simply blended into one homogenous mixture. If they were, the polyaniline would be diluted to the point that it would lose its conductivity. Instead, liquid solutions of the two substances are extruded from two separate (but closely spaced) nozzles, merging and bonding to form a single fiber which is cotton cellulose on one side and polyaniline on the other.

In lab tests, such fibers have exhibited excellent electrical conductivity while also offering the strength and flexibility of cotton. They have also been successfully used in textile systems that delivered power to an LED light, and that sensed ammonia gas.

It is hoped that once developed further, the technology could be utilized in applications such as patches on the uniforms of people like firefighters and soldiers, who need to be warned of exposure to hazardous substances on a frequent basis. They might also find use in fitness clothing that monitors the performance of its wearer.

A paper on the research, which was led by Assoc. Prof. Hang Liu, was recently published in the journal Carbohydrate Polymers.

Source: Washington State University via newatlas.com

TEXTILES.ORG

TEXTILES.ORG