Successful new developments and designs have prompted encouraging growth rates, but challenges remain.

A series of novel developments in medical textiles see smart textiles coupled with smart design to deliver benefits to both patients and medical professionals. With the medical textile market predicted to grow at a CAGR of 4.23 percent during the period 2018-2022, the industry is positioning itself to meet this demand.

Visual indicators

One of the ways to alert health professionals about changes in a patient’s condition is to use a visual indicator, such as color. Researchers at the University of Alberta in Canada and Kyushu University in Japan are investigating the use color-change technology in smart wound dressings. The approach is based on detecting changes in pH where a rise above 7.3 indicates the presents of an infected wound or chronic skin condition.

A pH Phenol red indicator dye is modified and introduced to an alginate/polyacrylamide (PAAm) hydrogel matrix with a covalent attachment used to prevent the dye from leeching out of the matrix, something that has previously been an issue impacting on reliability and the length of time that the dressing can be used. The intention is to use the colorimetric display as a smart and stretchable substrate for printed biomedical electronics in applications such as smart wound dressings.

Researchers at the Swiss Federal Laboratories for Materials Science and Technology, EMPA have been looking at the use of Pyranine-Benzalkonium ion pairing as a potential fluorescent dye for wound detection. Pyranine is non-toxic and offers a very precise ratiometric detection of pH readings. The quarterenary Ammonium salt Benzalkonium has potent antimicrobial properties and makes the Pyranine sufficiently hydrophobic to allow incorporation into membranes and wound dressings without interfering with its pH sensing capabilities.

Changing shape

NiTi, an alloy of Nickel and Titanium is the basis for Shape Memory Alloys (SMAs) that have the ability to change shape in response to heat stimulus, such as from the human body or generated by electricity. Its biocompatibility, flexibility and lightness make it ideally suited to medical and dental applications. It has been available for many years in the form of wires and sheet metal, but we are now seeing the emergence of more sophisticated SMA materials with structures closely resembling those of textiles.

Researchers at two Romanian universities, the University of Craiova and the Universitea de Medicina si Farmaci Craiova, have been investigating the potential of these alloys as a way of minimizing the size of medical devices to allow for less invasive, and therefore less traumatic, procedures. Knitted spacer fabrics provide cushioning for a wide variety of applications from sports footwear to bandages and seating. Shape memory spacers can be used in the treatment of scoliosis, where the ring-like device is placed between two vertebrae to provide local reinforcement and help to prevent any traumatic motion during the healing process. The use of the spacer allows a constant load to be applied whatever position the patient may be in.

In orthopedic implants, porosity enables body fluids to be transported from the exterior to interior of the bone structure. This is needed as part of the healing process. A porous NiTi SMA appears sponge-like in section, looking to the body’s own bone structure it offers a high compressive strength, making it suited to load bearing.

Cardiovascular disease is one of the leading causes of death globally causing an estimated 19 million lives each year. The first cardiovascular device that used an SMA was the Simon filter. This works as the device is kept in a (cool) martensitic state until the catheter releases the filter in position inside the body, where blood flow warms and causes activation of the device returning it to its former ‘memorized’ shape.

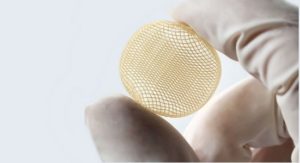

The Secant Group produce a number of neurovascular devices using textile technologies, such as knitting, weaving and braiding, to allow for minimally invasive procedures. These include a braided Nitinol flow diverter. Braiding structures can offer robustness and flexibility and are well suited to applications that require radial reinforcement and expansion, compaction, flexibility, porosity and highly angulated vasculature such as in neurovascular applications.

Developing a novel textile for a medical application can prompt new design solutions that go far beyond the initial concept. GlideWear is a low-friction fabric developed by Tamarack Habilitation Technologies that’s designed to protect vulnerable skin and soft tissue from the friction and sheer that can cause blisters, pressure injuries and even wounds. It was initially produced as a protective sleeve to fit inside a prosthesis, providing a layer of comfort for the amputee and avoiding friction between the body and the device.

While this remains a core application, the fabric is now being used as a mattress or wheelchair headrest liner to protect the skin of people with limited mobility, or those receiving long-term care. It is also being used to protect the fragile skin of children suffering from Epidermolysis Bullosa as well as burn victims, where it is incorporated into compression garments.

Research is now underway to look at the benefit it can offer to motorcycle and cycle helmets designs. Inspired by the way that cerbrospinal fluid acts as a protective layer between the human brain and the skull, the GlideWear fabric offers a layer of protection between the head and the helmet so that a small amount of movement is allowed in the event of impact. This 10–15mm of relative motion between the head and the helmet the manufacturers believe makes for a safer product.

Research and Market’s report, “Global Medical Textiles Market 2018-2022,” is optimistic about growth (as noted at the beginning of this article), but cautions that one of the major factors hindering market growth is the lack of effective recycling. While the need to address the circular economy applies to the whole of the textile industry, medical textiles have some unique problems around contaminated materials that have yet to be addressed effectively. This is a serious issue, but it also presents an opportunity for improvement and robust growth in the future.

https://www.youtube.com/watch?v=6FdhfLWtk9U

New medical textile developments from the Secant Group. Video: Secant Group

Marie O’Mahony is an industry consultant, author and academic. She the author of several books on advanced and smart textiles published by Thames and Hudson and Visiting Professor at the Royal College of Art (RCA), London. www.linkedin.com/in/marie-o-mahony-94776836

TEXTILES.ORG

TEXTILES.ORG