Organizers push for industry participation in the ongoing process.

By Janet Preus

Work is well underway, progress has been reported, and new initiatives have been launched. At IFAI’s Smart Fabrics Virtual Summit this spring, presenters Chris Jorgensen, IPC, and Stephanie Rodgers, Apex Mills, provided a comprehensive update on the development of international standards for e-textiles. IPC (Association Connecting Electronics Industries) based in Bannockburn, Ill., is spearheading the effort to establish standards for e-textiles.

Jorgensen, who is IPC’s director, technology transfer, explained IPC’s process for the development of standards, which he says ensures that every comment is resolved, and there is a balanced representation of users (end product manufacturers or brands) and suppliers (who manufacture materials), with consensus approval for decisions. For those participating in the process, it’s “free education on the standard topic,” he says.

Attendees made a number of key decisions at the first meeting in 2017, including five “actions:”

- Form a general committee to develop standards and provide technology solutions for the e-textiles industry

- Develop a functional characteristics and test requirements specification for e-textiles materials

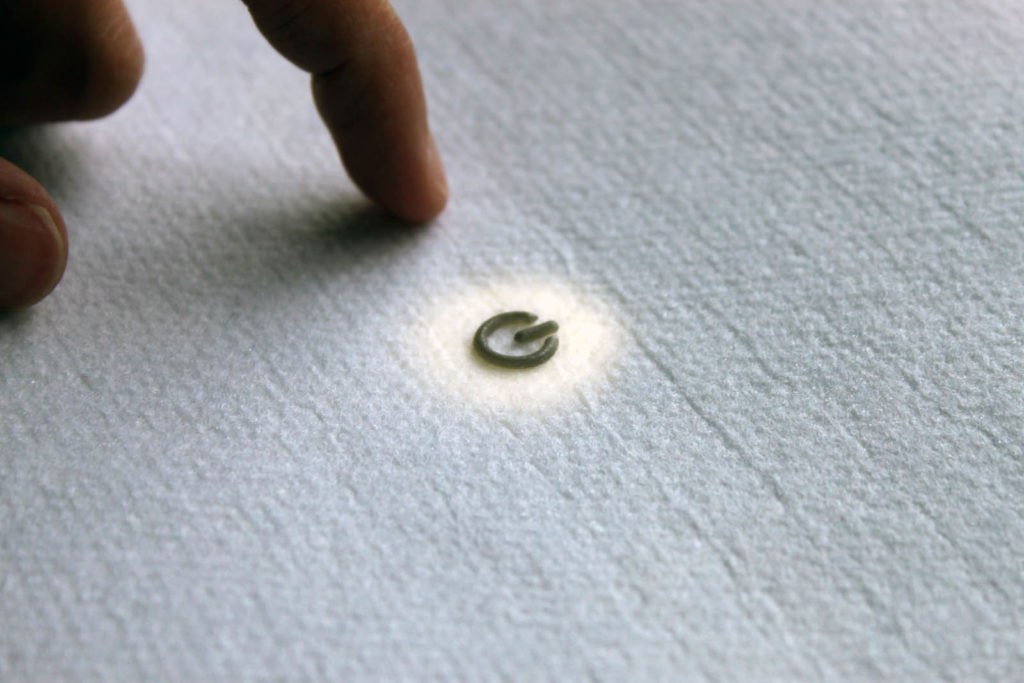

- Develop a guideline on connectors/processes

- Investigate needs for data collection and development of test coupon(s)

- Adopt terms and definitions

IPC-8921: the beginning

Seven topic families have been created, included IPC 8920 – E-Textiles. Under this number, IPC-8921 – Requirements for Woven and Knitted E-Textiles, Conductive Fibers and Conductive Yarns, was created, and work on D-72 E-Textiles Materials Subcommittee began almost immediately. Co-chaired by Stephanie Rodgers, Apex Mills, and Diana Wyman, AATCC, it has attracted 140 participants, and it submitted a working draft to D-72 for comments in February 2019. Publication of this standard is expected in Q4 2019.

IPC 8921 overall intends to:

- Establish classifications and designations for e-textiles integrated with e-fibers, e-yarns and e-wires

- Set new terms and definitions specific to the standard content –adopt other terms from ASTM

- Standardize Key Characteristics and Durability testing and industry test methods to be used

- Set quality assurance provisions and test frequency

It will not cover requirements for other types of e-textiles (nonwovens, coated/plated fabric, laminated, printed, braided, embroidered), nor will it include requirements for non-electronically integrated textiles or nonconductive fibers or yarns.

IPC-8941 is next

Work is also underway on the D-71-Textiles Joining and Interconnection Techniques Subcommittee. Connie Huffa, Fabdesigns Inc. leads this group with vice chair MaryAlice Gill, Nypro Consumer Health (Jabil). It has 75 participants and was approved to begin work in fall 2018. It expects to have content by early 2020 for the first D-71 review and comment.

Additionally, a D-74 Test Methods Validation/Development Subcommittee has been formed to work on the issue of test methods. Chair is Pratyush Rai, Nanowear Inc. and Jeffrey Lee, iST-Integrated Service Technology serves as vice chair.

White papers

Two peer-reviewed white papers have been published, as well. “IPC-WP-023: Washability Study of E-Textiles Structures with Silver-Coated Yarn” was authored by VladnaKoncar, ENSAIT GEMTEX Lab, D-70 Europe Chair. Also, “IPC-WP-025: Framework—Stack—That Can Be Used for E-Textile Development” was accepted from author Madison Maxey, LOOMIA.

Developments are moving ahead of schedule. Standard #8921 is going out for ballot this month (July 2019) and will most likely be published in the fall, which is earlier than expected, Jorgensen says. IPC uses an ANSI-approved process, which requires a 30-day call for comments to the industry. Jorgensen stresses than they are looking for a wide representation in responses from all parts of the industry.

“In this case, anybody who buys or uses a woven or knitted e-product,” he says. “The goal of this is to have balanced representation, so it’s not driven by the user or the supplier part of the industry.”

Also scheduled in July is a meeting to put together a task group to form a design standard for printed electronics/e-textiles. Jorgensen says that this would be for printed electronics on a coated textile, most likely, “although the task group will decide, so it could change, or they could develop more than one document,” he says.

IPC has also opened up a survey to get more industry feedback, asking companies and technologists to tell them what are the performance characteristics or test methods they’re using, or their customers are using, for wearable applications. “We’re keeping this pretty open ended,” he adds. Applications may be in sports, health, medical or protective markets, for example.

Starting from scratch

“When we first started working on the #8921 standard, we had a blank sheet of paper,” he says. A survey, similar to the one released regarding test methods, was done at that time. “We asked, ‘What are the important characteristics, and what tests are you using or adapting?’ That feedback helped to comprise section four of the document, which is the test requirements.”

Jorgensen is scheduled for a “fireside” presentation at IFAI Expo, Oct. 1–4 at the Orlando Convention Center. For more information and to register, visit ifaiexpo.com.

IPC E-Textiles 2019 will be held September 10-11 at Drexel University Center for Functional Fabrics, Philadelphia, Pa. For more information and to register, visit www.ipc.org. Also, IPC E-Textiles 2019 (Europe) will be held November 12-13, 2019, in Munich, Germany.

Janet Preus is senior editor of Advanced Textiles Source. She can be reached at jlpreus@ifai.com.

TEXTILES.ORG

TEXTILES.ORG