With close to $1.46 billion in investments since 2008, the commercial space industry is blasting ahead at speeds close to their supersonic vehicles. Key players include former Paypal co-founder Elon Musk, Amazon founder Jeff Bezos, and Virgin’s own celebrity Sir Richard Branson. Promises of breathtaking views of Earth’s curvature and the adrenaline rush from six seconds of weightlessness continue to allure industry and consumers alike.

Elon Musk’s company Space X is zeroed in on the long-term goal to establish a human civilization on Mars within the next 10-20 years. In the near term, Virgin Galactic will offer passengers suborbital flights to the edge of space with an eventual target of running daily trips from the Mojave Spaceport America. At altitudes far exceeding those of current commercial airline travel, passengers run the risk of increased exposure to space radiation. Agencies like the National Aeronautics and Space Administration (NASA) have continued to fund research on the effects of radiation in space, yet a demand for lightweight, non-toxic and low bulk textile solutions persists. Elements such as lead have typically been integrated into radiation shielding materials in the past. However, due to its toxicity and heavy mass, alternative replacements are essential.

Space radiation basics

Space radiation refers to ionizing radiation caused by solar flares and galactic cosmic rays. These high-energy particles are ordinarily deflected by Earth’s magnetic field, but at higher altitudes they can pierce through human cells and tissue causing damage to the body.

To fully understand space radiation protection, the standard shielding model of “higher mass equals increased shielding” does not apply. Instead, an element’s neutron capture range is used to determine effective attenuation. Elements such as gadolinium, boron and hafnium possess the highest neutron cross sections (NCS) and therefore prove to be excellent neutron absorbers. By utilizing elements with high NCS values, protective materials can be developed that have reduced bulk, non-toxicity and lighter weight.

Graded Z shielding

A common schematic for radiation protection includes the concept of Graded Z shielding. This involves the layering of multiple materials with different atomic masses (z values) arranged in descending order. Elements with high z values are placed at the exterior layer to absorb high-energy particles and attenuate radiation. This generates lower energy secondary radiation in each successive layer until it has been effectively reduced. In NASA’s current Extra Vehicular Mobility Unit (EMU), multiple layers of materials are implemented to provide thermal and foreign object debris protection. The EMU does not, however, provide adequate shielding from ionizing radiation. In “Material Choices for Mars,” NASA proposes the inclusion of two additional layers of radiation protective material to the EMU’s existing 14 layers.

Lighten up

David Horinek, of Hologenix LLC, recently identified the challenge to provide lightweight ionizing radiation protective materials and is currently developing textile and fiber compositions that adopt the use of high NCS value elements. Driven by a development proposal from the Canadian Space Agency, Horinek states that he “is interested in protecting humans in all ways that I can.”

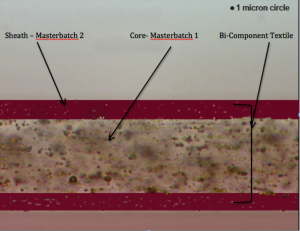

Woven fabric structures have traditionally proven difficult to manipulate due to holes inherent to their woven geometry. Horinek’s development concentrates on a bi-component core fiber and an external polymeric laminate film layer. The protective articles will be composed of a combination of these layers and will result in a lightweight sandwiched effect. His research has also expanded to include off-the-shelf nutrients that have been proven to absorb radioactive nuclei. Next steps for the protective material include further testing with heavy ion colliders, which are costly but imperative to echo the intense energy levels of space radiation.

Another team working on achieving low bulk and flexible solutions for the efficient capture of high-energy particles is Final Frontier Design (FFD) of Brooklyn, N.Y. Ted Southern and Nikolay Moiseev came up with the idea to merge nuclear reactor core shielding styles into NASA’s Thermal Micrometeoroid Garment (TMG). They were awarded a Phase I Small Business Innovation Research (SBIR) grant from NASA in 2013 to explore applications for their “Radiation Flexible Protection” innovation.

Also employing high NCS value elements, the company has experimented with incorporating nanopowders into a thin-film polymer matrix without compromising overall strength or flexibility. Southern states that their focus is on “reducing the bulk or profile of layers of radiation protection by integrating shielding onto pre-existing layers of the TMG.” Their proposal includes a Graded Z type shielding, and they continue to experiment with alternative methods to fuse these elements into films and fabrics.

Terrestrial applications

Improvements in radiation protection will not only enable the advancement of long duration human spaceflight but will also address the necessity for terrestrial personnel protection. Immediate real world applications have also been the focus of a number of researchers in the wake of disasters such as the Fukushima nuclear crisis.

Teijin Ltd., known for its high-strength para-aramid fibers, has developed a fabric that provides x-ray and gamma radiation protection intended for medical and emergency responders. The product combines their Technora para-aramid fiber with a high concentration of tungsten. According to Teijin, this high-density metal can be blended in varying concentrations to adjust the level of radiation shielding. Other notable properties include increased flame and cut resistance, as well as improved flexibility and wearability.

Teijin aims to target industrial end users such as law enforcement and first responders for use in protective clothing. This new development will also prove significant for safety workers in regions of Japan who are engaged in post-crisis reconstruction.

Satisfying the growing demand for radiation reducing material, Taiyo Kogyo Corp. and Hiraoka & Co. Ltd. have united to launch their product RaProTex. Short for “Radiation Protection Textile,” RaProTex is directed at lower level x-ray and gamma radiation environments such as contaminated radioactive soils and ash.

The material is intended to prevent water permeation and allow for the containment of radioactive substances. The polyester-based fabric is designed for use in sheets, bags and tents and contains shielding substances such as barium sulfate and vinyl chloride resin. RaProTex can be welded for weather-resistant construction and provides a flexible and low cost alternative to lead. The level of radiation protection may also be adapted using various layers of the material to achieve greater shielding results.

Opportunity and challenge

Current research supports the identification of increased radiation risks as the private space industry aims to launch customers into lower-earth orbit and beyond. A journey to Mars which can take anywhere from 150-300 days may seem far-fetched, yet shielding developments that enable reduced bulk and enhanced mobility possess tremendous crossover applications to lower level radiation environments found on Earth. With disasters like the Great East Japan Earthquake of 2011, risk assessment has been poignantly thrust into public awareness as safety personnel require lightweight and nontoxic textile solutions.

Critical advancements are beginning to take shape that tackle the high-energy ionizing radiation experienced outside of Earth’s magnetic field. These developments will play a key role in ensuring the safety of passengers as they embark on lunar and Martian expeditions. NASA has announced that its industry partners including Space X and Blue Origin are making rapid progress towards launching commercial passengers by 2017. Scenarios such as private inflatable space stations and lunar vacations will undoubtedly boast hefty price tags and limited customers, but the overall success of the burgeoning commercial space industry will greatly depend on material innovations that attack the issue of reducing radiation risks for passengers.

TEXTILES.ORG

TEXTILES.ORG