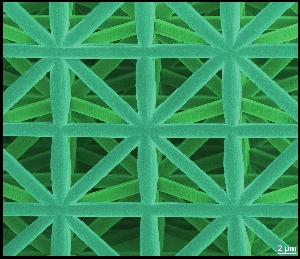

Karlsruhe Institute of Technology (KIT) researchers have developed microstructured lightweight construction materials of high stability. Although their density is below that of water, their stability relative to their weight exceeds that of massive materials, such as high-performance steel or aluminum. Inspired by the framework structure of bones and the shell structure of bees honeycomb, the materials “resemble the framework structure of a half-timbered house with horizontal, vertical, and diagonal struts,” says Jens Bauer, KIT.

“Nature also uses open-pore, non-massive structures for carrying loads [such as wood and bone],” Oliver Kraft, KIT, explains. At the same density, however, the novel material produced in the laboratory can carry a much higher load. A very high stability was reached by a shell structure similar to the structure of honeycombs. It failed at a pressure of 28 kg/mm2 only and had a density of 810 kg/m3. This exceeds the stability/density ratio of bones, massive steel or aluminum.

To produce the lightweight construction materials, 3D laser lithography was applied. Laser beams harden the desired microstructure in a photoresist, and this structure is then coated with a ceramic material by gas deposition. The structures produced were subjected to compression via a die to test their stability.

Microstructured materials are often used for insulation or as shock absorbers. Open-pore materials may be applied as filters in chemical industry.

TEXTILES.ORG

TEXTILES.ORG