The North Carolina Defense Manufacturing Community Support Program (NC DMCSP), which is administered by NC State University Industry Expansion Solutions, is disrupting the performance and functionality that once defined the traditional textile industry. With more than 40 percent of U.S. textiles produced in the state of North Carolina, NC DMCSP serves and supports textile manufacturers on the edge of discoveries that produce innovation in advanced textiles, wearables, and technologies that maximize warfighter survivability, lethality, sustainability, mobility, combat effectiveness and field quality of life.

A collaborative ecosystem

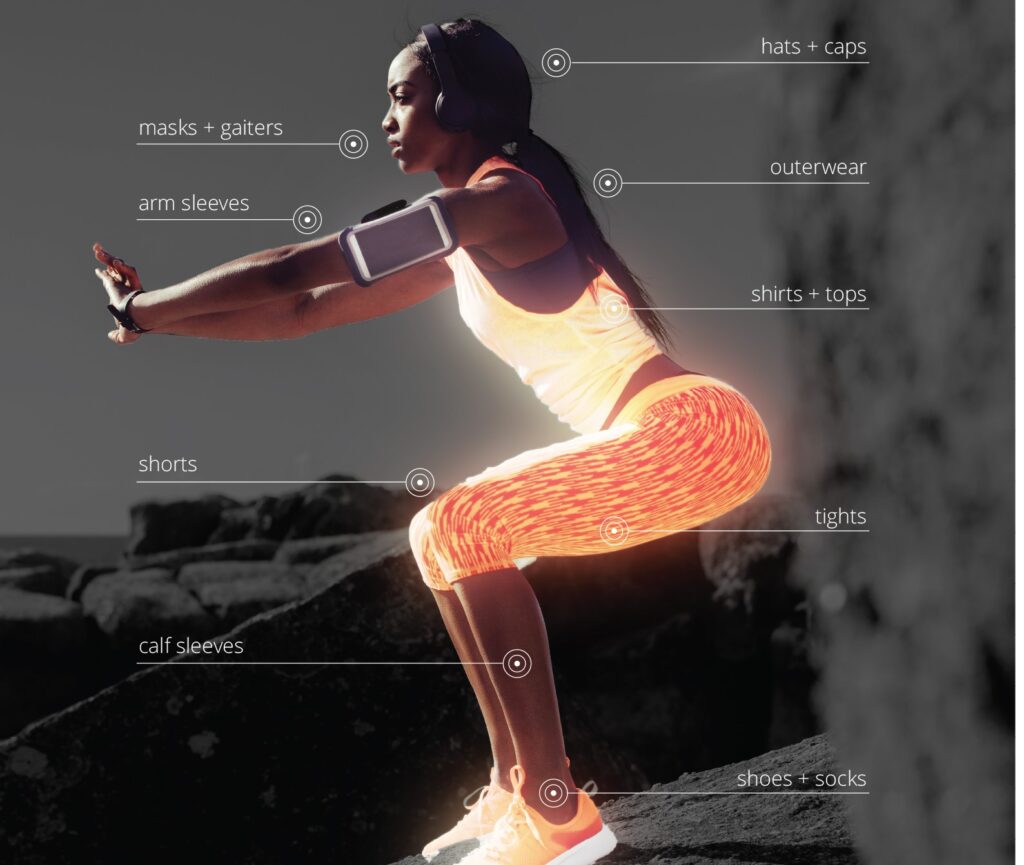

Funding provided through the Dept. of Defense (DoD) Office of Local Defense Community Cooperation (OLDCC) positions NC DMCSP to advance smart textiles to not only increase warfighter performance, but also add other functionalities, including health monitoring, communications, enhanced mobility, survivability, reduction of heat, camouflage and signature management, physiological status monitoring, and detection of chemical/biological threats.

NC DMCSP’s Ideation and Product Innovation team tracks DoD needs related to warfighter performance and health optimization, identifies potential solutions, forms teams to pursue funding opportunities and provides custom commercialization services. This team works closely with the NC DMCSP Entrepreneurship and Commercialization team to recruit and select participants for its “Propeller” program cohorts, and it assists in finding funding, technical support, facilities, partners and customers.

“We needed help finding its first customers. The NC DMCSP team researched the market for products addressing the problems Aarogy’s textiles solve, identified key players and introduced us to a leading apparel manufacturer in this space that is now evaluating Aarogy’s material,” says Catherine Burge, CEO, Aarogy Innovative Textiles LLC, headquartered in Raleigh, N.C.

Funding assistance is primarily focused on finding non-dilutive funding opportunities through DoD and other federal agency grant and contract mechanisms, but the team is also building an investor community around wearable and textile technology to fill gaps in funding from early- through late-stage development. The ecosystem needs all types of investors, from angel investors and venture capitalists, through corporate venture arms and private equity, to ensure an uninterrupted path to commercialization in the government and private sectors.

NC State Industry Expansion Solutions team members, Dr. Fiona Baxter, associate executive director; Michael Mullins, director, Defense Industry Initiatives; and Giles Beal, client relationship manager; are collaborating with more than 20 North Carolina organizations to provide scientific innovation assistance for entrepreneurs and manufacturers in the five different stages of the manufacturing ecosystem. The five pillars and goals of the NC DMCSP initiative include:

- Advocacy and outreach. Advocate, connect with, and enhance supplier network development for the North Carolina Textiles Manufacturing Defense Industrial Base.

- Ideation and product innovation. Identifies potential solutions, forms teams to pursue funding opportunities, and provides bespoke commercialization services.

- Entrepreneurship and commercialization. Help founders and entrepreneurs determine whether there is sufficient value to pursue a product or service idea and bridge the gap between a brilliant idea and the business value it represents.

- Manufacturing innovation and modernization. Build awareness of cutting-edge technology breakthroughs related to research and innovations to smart textiles and wearables for the warfighter.

- Workforce development. Enhance connections between the Textiles DIB and workforce development programs.

Innovation at work

Manufacturing smart textile technologies requires adoption of new manufacturing materials and methods (such as new fibers, yarns, inks, dyes embedded with advanced technology), smoother and more extensive innovation-production connections, and a technically skilled workforce.

The use of Artificial Intelligence (AI) in textile manufacturing is a relatively new technology capable of delivering higher quality fibers, fabrics and yarns for warfighter textile applications. Through the use of data and predictive analytics AI can help minimize variation between raw material, machine or environmental states, and the finished goods. Other implications for DoD include convergence of AI tools and use of predictive analytics for monitoring warfighter health and performance in the field.

Aarogy has developed a patented textile technology that reflects radiation in the far-infrared spectrum back into the body to improve blood flow and oxygenation, reduce cortisol, and increase the production of nitric oxide…providing multiple health and wellness benefits. By design, Aarogy technology can vary the amount of active fiber in their fabrics to optimize performance needs.

For example, using 75 percent active fiber in an Aarogy fabric delivered a zero burn score on the NC State Pyroman test and also cloaks the infrared signature of the warfighter. In addition, the FIR technology in Aarogy clothing improves focus, concentration, athletic performance, and recovery.

Smart and e-textile applications require a variety of microelectronics to collect, send and receive data. Successful integration of microelectronics into textiles for warfighter applications will support several DoD thrusts, including soldier systems, cybersecurity and biotechnology. Applicable uses in the DoD market include smart textile designs, liquid metals for stretchable conductors, fabric antennas and flexible printed circuit boards (PCBs).

A range of advancements

A sample of DMCSP entrepreneurs, manufacturers and research organizations with recent technological advancements shows the range of research and development supported.

Enhanced sleep. Nuream Inc. is a neuro data science company based in Wilmington, N.C. Its technology is enabled by novel, non-invasive neurocapture fabrics and materials that harness brain wave data to improve wellness, performance and healthcare outcomes. The company’s solutions are dual-use technologies and applications, improving the lives of warfighters and consumers, as well. Its applications fit in the current Brain Health Initiative (BHI), the CFT (cross-functional team) Warfighter Lethality, and multiple U.S. government agencies’ initiatives studying enhanced sleep opportunities.

The Nuream hypothesis holds that neurodata is the new decision support frontier and delivers a novel, non-invasive brain wave neurosensing fabric, then directs condition-specific algorithms to harness this protected neurodata. Nuream’s Brain Machine Body Exchange (BMBE) enables data-driven decision support to improve wellness, performance and healthcare outcomes.

Immediate applications of this neurosensing fabric include pillow coverings, wrist-based wearables, and performance or wellness wear. While the technology addresses sleep as the first targeted outcome, there are many other outcomes it could improve, including concussive injury assessment and recovery, PTSD/TBI improvement and neurological disease states.

Light harnessing. Lumiton, based in Charlotte and founded by North Carolina residents Dr. Marco Scipioni and Gates Hinds, has developed and patented sustainable, synthetic, Light-Smart™ clothing that harnesses sunlight and emits red and near-infrared light. This light-harnessing fabric technology gives consumers, for the first time, access to the cellular-level wellness of “red light therapy” via everyday clothing. Clothing that uses Lumiton technology is also exceptionally cool and UV protective. The company’s founders say, “Given what we now know about how our bodies thrive on light energy, wearing clothing made with Lumiton technology is simply a smarter way to live under the sun.”

Many benefits have been associated with red light therapy, shown to impact cellular energy, collagen production, blood circulation, lymph system activity, tissue oxygenation, tissue repair, muscle growth, antioxidant activity, muscle recovery and even hair regrowth. The markets applicable for the technology include activewear, healthcare, workwear and the military.

Transforming clothing to provide light-driven wellness elevates synthetic fibers into a new class of useful goods. The product’s yarns are solution-dyed which uses up to 95 percent less water and 85 percent less energy than traditional dyeing, and the technology is compatible with recycled polymers. Additionally, solution-dyed yarns generally improve wash fastness and color fastness.

Chem-bio threat detection. Rock Spring Bio is developing enzyme-based technologies to detect and/or remediate chemical and biological threats through wearable sensors and textile treatments. Applications include wearable sensors for threat detection, anti-biofouling products for chemical and biological hazard mitigation, therapeutic peptide production, liquids, textiles, and nanoparticles of anti-microbial products.

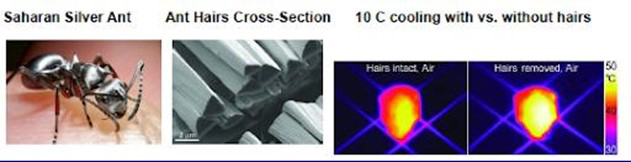

Using biomimicry. Small World Sciences LLC, Morrisville, N.C., partnered with NC State University to develop fibers and textiles with infrared (heat) reflective and emissive properties based on biomimicry of the Saharan Silver Ant, which evolved to survive in extreme desert conditions. This unique concept has been scientifically validated through a National Science Foundation-funded project at Columbia University.

Pain-relief fabric. Nufabrx, a graduate of the Manufacturing Solutions Center’s incubator program, was included in Inc. 5000 No. 50 fastest-growing private companies in 2021 by innovating the pain relief market. In collaboration with AFFOA, the company developed fabrics infused with pain-relief medications.

An invitation

Diverse products necessary to maximize the warfighter’s survivability, lethality, sustainability, mobility, combat effectiveness and field quality of life necessitates considering the warfighter as a system and includes textile-related items such as body armor, clothing and footwear. The commercial market provides stabilizing revenue for existing defense contractors and opportunities for new players to modify commercial gear for the defense market.

The goal of increasing the number of North Carolina textile companies participating in the defense industry base (DIB) ultimately contributes to a more resilient DoD supply chain. NC DMCSP also recognizes the critical need to provide leadership and sector-collaboration that addresses issues involving the circular economy.

Dr. Fiona Baxter is associate executive director of NC State’s Industry Expansion Solutions, assistant director of the NC Manufacturing Extension Partnership, and and Principal Investigator of the NC DMCSP. Michael Mullins is director of Defense Industry Initiatives at NC State’s Industry Expansion Solutions.

TEXTILES.ORG

TEXTILES.ORG