The Advanced Textiles Association Emerging Technologies Conference (ETC) in Indianapolis, Ind., Nov. 4. offered attendees real-world mechanisms for moving their businesses forward in a changing industry landscape. Two presentations dealt with entities established specifically to support research and development, connect various areas of expertise and provide the means to move innovations into commercialization.

Advanced textiles: pushing the boundaries

For 13 years the Advanced Functional Fabrics of America (AFFOA) has been a leading driver in the development of new textile technologies, helping startups and established businesses alike in pursuing ideas that benefit from AFFOA’s expertise and mission to accelerate the process to commercialization.

Dr. Michal Rein, director of engineering, AFFOA, spoke at ETC on the topic “Pushing the boundaries for dual-use applications.” The session, however, moved beyond “dual use” specifically, and covered multiple examples of AFFOA’s success stories, and new projects underway. These projects represent a range of industry markets, including defense and security; healthcare and medical; protective and safety; performance and lifestyle; industrial and architectural; aerospace, maritime and automotive, as identified by Rein.

Recent projects include partnerships with industry to develop bio-derived fibers; creating a large-scale PFAS treatment; heater and tactile sensing, as well as tactile sensing for robots; AI-enabled diagnostics for home-based healthcare; conductive inks; e-textile webbing, and others.

Rein notes AFFOA works to overcome barriers to scalable solutions. “There’s a gap in the manufacturing community in how to scale up,” he says, and he points to the lack of advanced digital design tools. “Design tools are pretty commonly used in other industries, but [many in the ] textile industry have used a single tool, maybe, or not at all.”

There are also “skilled workforce gaps,” he says, which presents a big challenge to many manufacturers, so AFFOA is also trying to “reduce the entry challenges for new workforce members,” he says.

Using the example of e-textile products in development, Rein says that designers and manufacturers can spend significant time and money designing products on their own. Others are simply hesitant to develop them due to “technological gaps and lack of prototyping infrastructure.” That’s where AFFOA’s access to expertise and processes can reduce barriers to development and manufacturing and “actually get the product to market.”

To do this, AFFOA developed infrastructure resources for three foundational e-textile elements—conductors, encapsulation and connectors—creating a universal development platform (UDP) for e-textiles, which enables developers to focus on textile functionality while minimizing hardware and software efforts.

“What our team has done is design an Arduino [an electronics platform] for e-textiles,” he says. “It’s an open-source tool that our members can leverage. … You don’t have to start from scratch.”

Addressing the needs presented by the U.S. Military/DoD is an on-going challenge, especially reducing the amount of weight soldiers carry, which has continually increased over the years. In fact, even with the gear and devices a soldier must carry, “the textiles actually are about 45 percent of the total weight,” he says.

A Request for Information (RFI) regarding the DOD’s Design for Manufacturability and Business Case Analysis was recently issued, which offered an opportunity for those “in the cut-and-sew, automation and manufacturing technology sectors to support clothing and textiles modernization.”

“We want to know about any mill making uniforms,” he says, due to interest in developing “a new type of uniform, or improving the production process.”

The Textile Innovation Engine of North Carolina

This presentation by Baily Smith, Extension Coordinator, Zeis Textiles Extension at NC State, outlined the purpose and accomplishments of The Textile Innovation Engine of North Carolina (Textile Engine) in driving growth in the textiles industry. Its stated mission, in part, is “to advance the competitiveness of America’s textile industry through research, development, and commercialization of next-generation materials and processes.”

As a regional “catalyst for global innovation,” the Textile Engine has to date supported 200 businesses in research and development projects; sustained or created 5000 jobs, educated 30,000 students and workers, and converted 200 million pounds of waste into circular goods.

The Textile Engine has 24 projects underway with its partnerships. Some align specifically with sustainability objectives, including mechanical and chemical recycling methods; biobased yarn development; 3D bioprinting using cellulose waste. Hemp is the focus of two projects: one is working to build a hemp consortia, in an effort to support hemp processing and hemp yarn development.

“We are trying to de-risk,” she says. “The farmers don’t want to grow it, unless there’s a market.” Another project plans to develop wound-healing textiles with hemp.

Its research output by the numbers boasts several publications either published, submitted or underway; new adopted standards; one patent completed; and about $1 million in new funding.

An interesting component of the Textile Engine’s objectives is workforce development by building a “strategic roadmap,” led by “an integrated cross-educational work team.” The goal is an “integrated continuity of experience for current and future textile workers and students,” specifically for and with the N.C. Dept. of Public Instruction. “There will be more than 5,000 students who will take this curriculum this year,” she says.

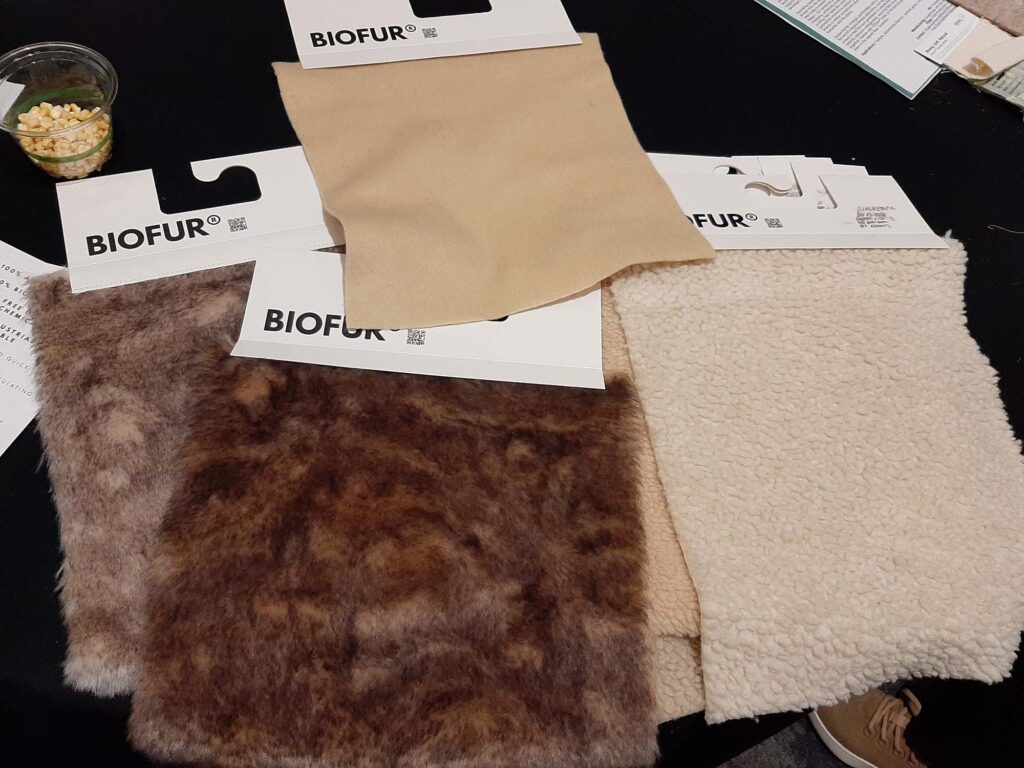

Valorizing waste and the biomaterial revolution

The growth of biomaterials—fibers and fabrics—has been well documented in this publication. ETC presenter Thomasine Dolan Dow takes it a step further and calls it “a revolution” in next generation fibers, materials and coatings. In her presentation she also argued for “giving value to waste, by “transforming overlooked, discarded byproducts into something valuable.” This could include waste from agriculture, plants, food and textiles.

Bio-based is “nature based,” she says, consisting of materials “that can be grown again and again, such as corn, potato, sugarcane, soybeans and grains. Emerging next-gen feedstocks include mycelium, agricultural waste, seaweed, kelp and algae, with market growth well underway. In 2023, the next-gen material market forecast was valued at $73.38 billion. The forecast for 2030 is slightly more than $139 billion.

Dow stresses that it’s important to care about the environmental impact of “more stuff, including single use items,” generated by an increasing population. Further, with climate change and the subsequent changes in weather patterns, the normal supply chains are starting to break down, she says, “So, we need to prepare to change.”

Additionally, there’s also significant evidence that petroleum products, such as polyester, nylon and acrylic can shed microplastics that do not break down. This is especially worth noting, as 60 percent of apparel is now made from fossil fuel.

“It’s really hard to compete with polyester and with plastic in general because it’s so cheap—and it’s been subsidized,” she says. Today, however, there are many companies that have successfully commercialized biosynthetic materials and biofibers. “Biosynthetics are particularly intriguing,” she says. “They could eventually replace petroleum-based plastics and nylon.”

She also listed many recycling companies, and provided a substantial list of companies making performance biocoatings and dyes, which are “really important,” she says, “Because once you put a petroleum coating on, you can’t recycle it.”

Sustainably protecting agricultural workers

In a presentation titled “Circular thermoregulating textiles,” Dr. Cindy Cordoba, asst. prof. at California State Polytechnic University, Pomona, explained the HeatShield Apparel Project, which seeks to address the dual challenge of worker safety and sustainability.

“Agricultural workers are under-protected in this climate,” Cordoba says. According to a report from 2015 that she cited, “Agricultural workers are 35 times more likely to die from heat exposure than those working in other sectors. The average worker faces 21 days in unsafe heat conditions.”

However, because workers often are paid by the pound that they pick, not by the hour, “Sometimes workers are thinking about productivity, which is important, instead of their well-being,” she says.

Cordoba notes that this is not a project that’s researching and designing new technologies or innovations, but one that seeks to use available heat transfer solutions, which textiles can address in various ways:

- Radiation from an external source, such as the sun: the textile can block or reflect the heat.

- Conductive heat transfer through direct contact: the textile can insulate or pull the heat away from the body.

- Convection involves heat carried by moving air: the textile can either allow air penetration or block the wind.

- Evaporation, which is the body’s primary cooling system: the textile can pull moisture from the skin and release it.

Protective textiles can be simply passive, enhancing the body’s natural cooling; responsive, such as with smart fabrics that adapt to environmental conditions; or active cooling, powered garments or devices that provide maximum cooling.

Coated fabrics, such as with carbon nanotubes, or various engineered composite fibers can offer high thermal conductivity and are generally more durable than coatings, which can crack or delaminate.

There are solar reflective fabrics, and infrared transparent materials that allow the body’s own mid-infrared (mid-IR) radiation to pass through the fabric and escape. Cooling can be achieved with membrane laminates: a three-layer fabric that holds water in a central core and evaporates to cool the skin. Adaptive textiles, using shape memory alloys (SMAs), automatically changes in response to an external heat source.

When a passive or responsive solution is not enough, “We have active cooling,” she says, with micro-fan ventilation in the form of battery-powered fans integrated into a vest or jacket. The problem with this system is that in extreme heat it can blow hot air onto the worker. “That’s why it’s good to combine with other cooling mechanisms,” she adds.

The project is following basic circular design principles in order to make their solutions sustainable as well as functional. This means addressing the longevity and durability of the material; it’s flexibility in use (modularity); and it’s ability to be disassembled. The material also needs to be non-toxic, as well as high performance. Further, the project follows “system thinking,” which considers “the interconnectedness of user needs, technical requirements, and broader social, technological and environmental systems.”

“Next-life” pathways are priorities in material and products, with “repair” at the top, followed by component reuse, recycling (mechanical or chemical), and composting. “Burning it up,” or energy recovery, is a last resort.

Janet Preus is senior editor of Textile Technology Source. She can be reached at janet.preus@textiles.org.

TEXTILES.ORG

TEXTILES.ORG