Editor’s note: Early in my career writing about functional textiles, the board chair of what was then the Industrial Fabrics Association International walked me through the JEC show, running concurrent with our Expo. He gestured around the displays, most of them featuring rigid composites, and said simply, “There are textiles in everything here.” We might be more likely to label them fibrous substrates, or even just “fibers” today, but the fact remain: there is a large market for them in an industry that might seem far removed. Dr. O’Mahony’s feature, however, will help to make some connections for us. – jp

The sports industry has long been one of the key innovators in new materials from apparel to footwear and sports equipment. The global sportswear market was estimated at $335.92 billion in 2023 and projected to reach $646 billion by 2030, growing at a CAGR of 9.9 percent, while the sports composites market was valued at $3.82 billion in 2023 and projected to grow at a CAGR of 5.8 percent during the same period, according to two reports from Grand View Research.

In this feature we look at the use of 3D textiles, including robotic fiber laying and composites, examining the innovations that they are bringing to sporting goods, vehicles and footwear. Performance and lightness remain key drivers, but they are now joined by the growing consumer demand for sustainability.

Flax in sports equipment

With world champion tennis players like Carlos Alcaraz using a Babolat Pure Aero 98 flax tennis racquet, a more sustainable product has shown that it is more than capable of enhancing performance. EcoTechnilin demonstrates the potential of flax in sports equipment in its partnership with Babolat for the latter’s “Pure” range of tennis rackets.

Flax is used to technical advantage, as well as environmental. This is achieved through the layering of the flax coupled with the mechanical stiffness and mechanical properties of carbon fiber, according to Thibault Roumier, development and technical sales director with EcoTechnilin. He sees additional benefits to be had with better vibration damping and improved player comfort.

“We are not talking about a smaller project anymore,” says Roumier. “We are talking about one of the key players of the tennis market with high technicity in the racquet.”

The company has also developed a pickleball racquet that is fully recyclable using flax and polypropylene, offering a significant reduction in CO2 emissions, and it has the additional advantage of increasing the “sweet spot” during play.

Padel has over 30 million players worldwide, according to the International Padel Federation, with Europe, where the game originated, being a particularly strong market. Widely regarded as the fastest growing sport, the market size is forecast to reach $.87 billion by 2033 from $0.29 billion in 2024, registering a CAGR of 12.93 percent during the forecast period, according to Business Research Insights. Within the market segmentation the padel racquet is expected to account for around 75 percent of this market, followed by footwear.

At present, a standard padel racquet can be expected to last 6-12 months before it delaminates or breaks because of impact. While tennis racquets can be restrung and last for many years, this is not the case with padel although it has a comparable price. ComPair has developed the HealTech padel racquet that can be repaired.

The composite uses a repair technology that’s embedded in the resin, which combines with glass, carbon or flax fibers for a versatile solution. It’s available in the form of a prepeg or a Liquid Composite Moulding (LCM) that allows microcracks to repair at 100C to extend the lifespan and reduce CO2 emissions by up to 99.6 percent when compared to disposal.

ComPair is part of the NERTHUS consortium of Spanish, Swiss and Italian companies who were awarded €2.8 million Eurostar funding in 2024 for the development of sustainable composites for Green Mobility.

Carbon fiber’s versatility

Demonstrating the versatility of textile manufacturers, Toray’s carbon fibers are used in very different ways for bicycle and footwear design engineering. In footwear engineering their continuous fiber-reinforced thermoplastic (CFRT) composite allows designers to tailor the range of foot motion through a combination of component design, fiber placement and resin selection.

In athletic footwear, it can be used as a single plate, or in specific areas. When used in the spring or propulsion plate that extends into the foot’s first or second metatarsal, it can offer enhanced spring and resilience. Used in the heel plate, it helps to stabilize the heel during heel strike to minimize pronation and supination. Used in an insole it has been shown to reduce foot fatigue and offer improved stability, while its thinness and thermoplastic quality allows it to be adjusted using heat for individual comfort.

With a focus on strength, lightness and speed, Toray Carbon Magic, in collaboration with the High Performance Center of Japan Cycling, has developed what they believe to be the world’s fastest bicycle. It uses TORAYCA carbon fibers that were originally developed for the aerospace industry, while utilizing Toray Carbon Magic’s sophisticated computer simulations, rigorous testing and real-world evaluations.

Precision with robotics

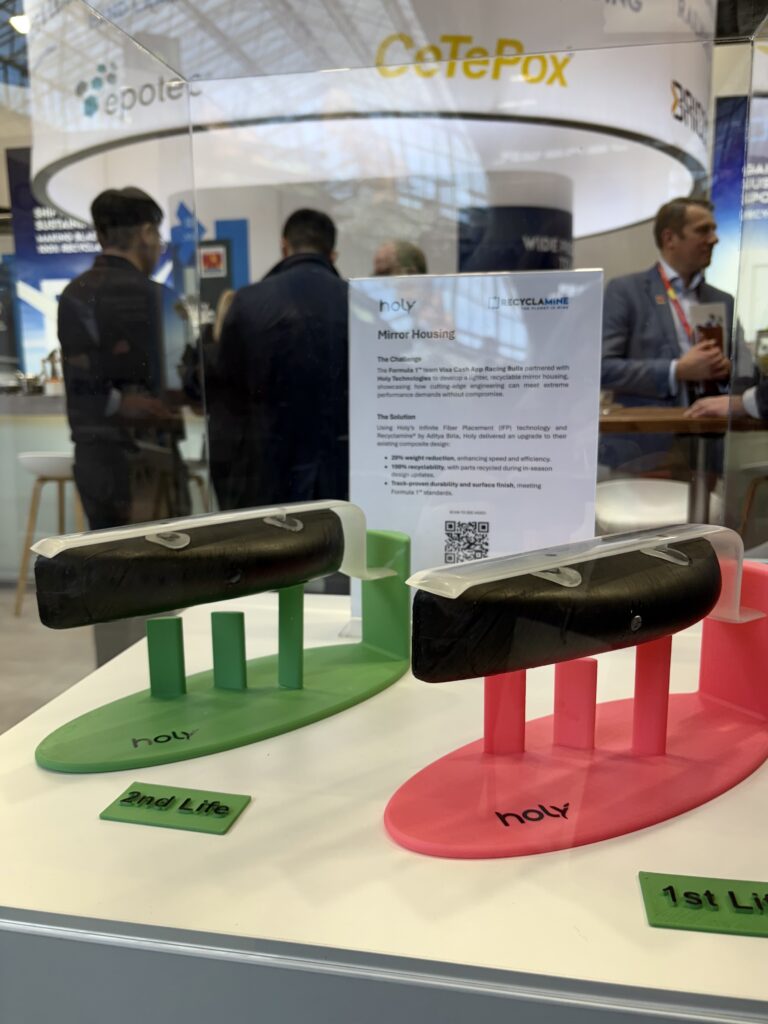

Formula 1 racing teams push the boundaries of what is technically possible to achieve greater levels of performance. In a collaboration with Visa Cash App Racing Bulls (VCARB), Holy Technologies have developed a fully recyclable wing mirror casing that is lighter and capable of meeting the stringent technical requirements. Conventional methods for making a prepeg relies on materials where the fibers are pre-aligned. This means that the same amount of material is used throughout, so that areas where little performance is needed still have to use the same amount of material as the high strength areas.

Looking to robotics, the process used here is Holy’s Infinite Fiber Placement (IFP) that allows for one continuous carbon fiber to be placed very precisely by the robot in a recyclable epoxy resin. This results in an optimization of the fiber paths that allows for weight reduction without compromising structural integrity. The double-walled 3D geometry enables a 20 percent weight saving and can be fully recycled because of the manufacturing process-use resin selection.

In these developments for 3D textiles, the knowledge and expertise draws on a very broad range of areas from design to sustainability, robotic manufacturing and digital technologies. While some of this is in-house, increasingly it is through cooperation that many of these advances have been achieved. We are undoubtedly entering an exciting period of collaboration across disciplines and borders.

Dr. Marie O’Mahony is an academic, industry consultant, author and a regular contributor to Textile Technology Source.

TEXTILES.ORG

TEXTILES.ORG