Functional textiles are the wave of the future, having huge growth prospects that will influence the survival and growth of the global textiles sector. Market analysis firms have, in recent years, been actively estimating the size of this sector. The field is varied, and hence the type of functionalization and the product types and applications vary, making estimation complicated. However, from the reports available, it is possible to examine likely growth trends.

According to Growth Market Reports, the value of functional textiles globally is about $220.6 billion, with an estimated annual growth rate of 8.2 percent. This report predicts the value of this sector to be $439 billion by 2033. These statistics show that, like the nonwovens sector, the growth rate is noticeably greater than the GDP growth of many developed economies.

Due to the need for high performance applications that support better health and protect the environment, for example, the demand for such products will grow. Importantly, the need to sense, adapt and vary the characteristics of materials according to the surroundings is getting the attention of consumers, researchers and the industry alike – all of which can spark investment.

Inherent or added

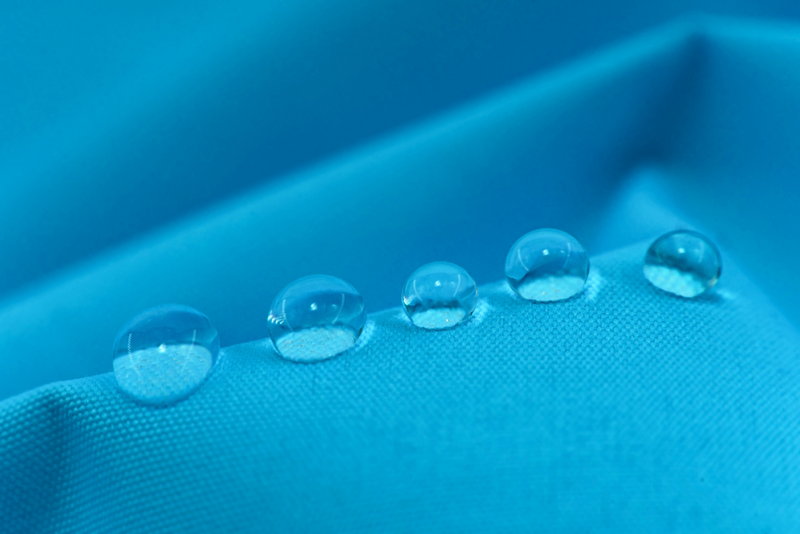

Functional aspects which are visible, such as water repellency or oil absorbency, often are provided due to hidden attributes, inherent in the basic structures that form the textile product, or as added formulations that impart the functionality by chemical bonding and reaction with the substrate or external medium. An example is the thermal physiological comfort of textiles, primarily based on an invisible functionality, which depends on the porosity and the fiber structural aspects, which determine comfort level.

Active functionality can be both inherent and provided by the application of external agents, such as chemical formulations, surface alterations and enhancements. This field is advancing rapidly with the support of multidisciplinary approaches, involving various scientific disciplines, such as high-energy physics, supercritical fluids, metal-organic frameworks, nano-surface alterations, graphene combinations and others.

The next phase

In this next phase of the textile industry, materials have both active and passive functionality: passive functionality provided by the structural and inherent physical and chemical characteristics of the basic structural components of textiles.

A strategic approach from the industry and investors in research will enable us to identify new functionalities, create superior value-added products, and deliver them to the market based on consumer interest and need. Optimum prices that consumers will be willing to pay will drive commercialization and grow the market.

The textile industry has paid attention to this field by focusing on the chemical aspects of functionality, which is now at a fairly mature stage. Clues on the nature and chemistry of materials and products, such as self-adhesives, color-changing and photonic textiles, have emerged and have been commercialized.

Enhancing and developing functional fibers (both natural and synthetic) is in its infancy. In this category of textile materials, fiber functionality will be a game changer. The synthetic fiber industry has a lead in imparting functionality at the fiber level. Functionalized and texturized filament forms, catalytic fibers and filaments, and high-surface fibers are some notable developments in this area.

Functionalization and nonwovens

Nonwoven fabrics are used in single-use or semi-durable applications. Therefore, the need to develop cost-effective products is a necessity in these markets. The economics and technology of spunmelt nonwovens demand the need for cheap thermoplastic polymers, and hence polyolefins are commonly used.

With nonwovens, the first-generation nonwoven products where hydrophobicity was in need, polyolefins were the best choice. In the next generation, there were demands for hydrophilicity, comfort, moisture vapor transport and hence surface or material functionality became a necessity.

The medical sector’s needs have increased, and comfort levels of medical drapes and cover fabrics, as well as hygiene, have gained importance. Factors such as breathable barrier fabrics, absorbent/adsorbent fabrics, hydrophilic spunmelt nonwovens started to emerge.

Sheath and core spunmelt fabrics, islands-in-a-sea spunbond fabrics and high-surface-area fabrics were possible due to mechanical engineering developments, micro/nano hole spinnerets, advancements in polymer chemistry and characteristics, as well as other factors.

Emerging technologies

The advanced textiles sector is well positioned to borrow emerging techniques from physics, chemistry, biology, and artificial intelligence to develop the sector. Advanced industrial textiles use synthetic materials that are more inert compared to natural products, and hence high energy, more functional resources might be needed to functionalize the surfaces.

Plasma techniques are well suited to excite the surfaces of polyolefins, aramids and polyesters; textile fiber surface modifications can be achieved using vacuum and atmospheric plasmas. The textile finishing industry has been utilizing plasma processes to impart surface functionalities, including water repellency, odor removal, oil repellency and insect repellent.

From a cost, logistics and energy point of view, atmospheric plasma offers commercial viability, and in the current market, pilot and full-scale atmospheric pressure continuous plasma functionalization lines are available. However, knowledge transfer workshops are needed to generate more interest in these systems. North Carolina State University pioneered the optimization and utilization of continuous plasma jet technology at atmospheric pressure levels. The effort utilized ionized gas as a carrier for chemicals to impart high-performance characteristics.

The plasma coating processes made it possible to do one type of coating on one side of the fabric to have repellency, while the other side of the fabric could have another treatment, such as to absorb moisture. Plasma gas treatment can achieve surface activation as well as surface etching to vary the surface area.

Chemical functionalization such as chlorination of plasma-treated fabrics results in antimicrobial fabrics. In such projects, the effect of plasma is hidden, while actual functionalization happens due to the chemicals used.

A recent plasma research program at the Nonwovens and Advanced Materials Laboratory at Texas Tech University focused on both vacuum and atmospheric plasmas. A unique aspect has been that, in this approach, plasma gas is itself a functionalizing agent to alter the surface characteristics of spunmelt nonwovens and woven textile fabrics. Plasma functionalization created micropores enabling hydrophilic spunmelt fabrics to be breathable.

Active functionalization by plasma gas has resulted in the creation of next-generation medical fabrics. Spunmelt medical drapes, while providing excellent bodily fluid repulsion, do not have the necessary comfort level for medical practitioners over prolonged use. But sustainable plasma surface activation imparted good moisture vapor transmission, enabling comfort for surgeons and nurses.

Both active and passive plasma treatments are yet to reach a level of full utilization in the advanced textiles industry. The industry must undertake cost-benefit analysis on the use of these green technologies.

High performance in natural products

Leading organizations such as the Advanced Textiles Association (ATA) and American Association of Textile Chemists and Colorists (AATCC) are in a position to offer workshops and promote the use of these emerging technologies based on technology evaluation and cost-benefit analysis.

Although chemical and physical treatments, surface alterations and enhancements have been proven to impart new properties and create high-performance applications for textiles and nonwovens, natural fiber phenomenon on its own can also provide certain value-added properties. These often remain “invisible” and passive, but these natural phenomena can be observed and mimicked to develop sophisticated textile materials with value-added properties.

This field, however, is nascent but it will provide an impetus for the textiles sector to invest in advanced materials research and exploration. Bioinformatics, modeling, genetic engineering, and generative artificial intelligence are disciplines that will help to enable revolutionary functionalized textiles.

The advanced textile sector is a major consumer of synthetic and high-performance fibers due to the requirements in its end products. In next-to-skin comfort and thermal comfort, thought, natural fibers have advantages. In fact, cotton is presold on its comfort and moisture vapor transport.

Natural fibers, such as cotton, face other challenges, however, including environmental and weather factors, extra processing requirements, and costs associated with these can impact this sector negatively. If the natural fiber sector can strengthen its focus on its unique selling properties (USPs) such as feel and comfort, it can overcome barriers and influence the advanced textiles sector in a positive way.

New approaches

Identifying USPs and focusing on enriching them, both in the case of natural and synthetic materials, will be the next step for the advanced textiles sector. For natural fibers (particularly cotton) its USP is comfort, but how can this property be enhanced or standardized at the fiber level? The answer could be found in using genetic engineering and bioinformatic approaches to tackle such complex but important problems.

If the agriculture and textiles industry partnership could identify superior cotton with superior comfort and feel, it could be widely used in sportswear, and activewear fabrics with superior comfort. This will also enable the performance wear industry to have greener choices and make the industry more environmentally friendly.

As a case in point, a research project at Texas Tech University identified certain sugars (large molecule oligosaccharides) having correlation with the amount of moisture vapor transport as these sugars influence the physical structure of fibers. A multidisciplinary approach will help to express those sugars in cotton, which can enable excellent moisture transport and eventually result in superior comfort fibers.

Such projects need the support of federal agencies like the U.S. Dept. of Agriculture (USDA) and DoD, due to the cost, time involved and uncertainties that accompany such long-term projects. In the case of synthetics like aramids, issues such as the impact of sweat, shear slippage and others need to be tackled at the polymerization levels.

The projects mentioned above focus on enhancing the performance of both inherent and added functionalities by physical and chemical approaches. Functionalities can also be developed with the help of blending and the use of additives.

For example, the active component in antimicrobial formulations is chlorine molecules, which are needed to do the job of countering the microbes. In some cases, the amount of available active molecules may be less, or the solution is complex, so the question becomes, how does one get maximum functionality in these circumstances?

Recently, interest has been growing in using bulk materials, which are cheaper, and with those large quantities the necessary functionality can be achieved. This method has been followed in herbal medicine, known as “Anupaana.”1 The chemical and material industry can explore such approaches to develop new functionalities in cost-effective ways.

Chennai, India–based Asthagiri Herbal Research Foundation is pioneering efforts in this arena and is actively seeking collaborations to take this approach to different markets. Healthcare and hygiene textiles will be immediate beneficiaries for such partnerships.

Moving forward

The advanced textile sector, which is functionality-based, focuses on three vital areas: health, defense, and environmental protection. Imparting high-level functionalities into textiles so that the products become active have the potential to save lives and could be the future for the sector. The industry must go beyond its comfort zone and explore new partnerships and engage in inter- and multi-disciplinary approaches to develop cost-effective active functional materials.

Currently the industry is active in exploring micro and nano materials. Learning from nature and modeling them to develop products in a sustainable way will be a game changer for the industry.

Active collaboration with genetics and bioengineering, artificial intelligence, and advanced materials sectors will be important in supporting the creation of innovative products. But R&D investments are needed for generating disruptive ideas to take the advanced textiles sector beyond 2035.

Dr. Seshadri Ramkumar is a professor in the Department of Environmental Toxicology and The Institute of Environmental and Human Health, Texas Tech University, and a regular contributor to Textile Technology Source.

1More typically associated with health practices, anupaana refers to the medium through which a drug is administered, such as water, honey or milk. The concept may also be applied to enhancing textile characteristics by using a carrier medium, which may also add to the materials functionalities.

TEXTILES.ORG

TEXTILES.ORG