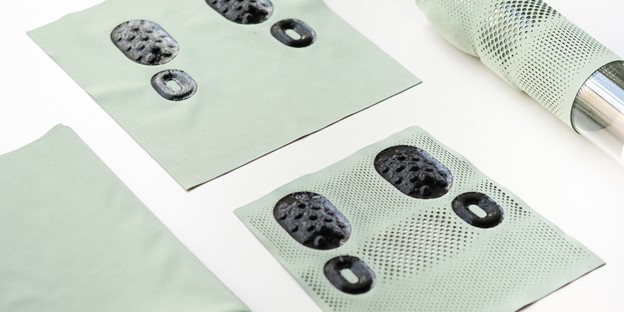

The +/- Brace is a user-centered, customizable elbow brace produced by combining additive 3D printing and subtractive laser-cutting technology. Designed by Nils Sorger during an internship at WertelOberfell, the brace can relieve pain, promote comfort and reduce the risk of injury or irritation during demanding physical tasks or sport activities.

Taking the user’s data and existing users’ measurements into account, the scripted algorithm calculates the optimal design for each individual’s personalized +/- Brace. The user could then either fabricate the brace on their own, order it within the maker community, or proceed with purchasing it on the platform. Users can also customize size, form, structure and padding using the accompanying app.

With this product, Sorger addresses challenges with conventional medical products, which are often unaffordable or not individualized, by enhancing efficiency in 3D printed, fabric-based manufacturing and embracing an open-source process. Utilizing Grasshopper with a custom-built script, the designer put in body measurements as parameters to generate data output for an FDM printer and the laser cutter.

Combining 3D printing and laser cutting in one device, complex shapes and structures can be produced that would be difficult to realize with conventional manufacturing methods. The chosen 4-way stretch softshell fabric is composed of 49 percent polyester, 30 percent polyamide, 12 percent polyurethane and 9 percent elastane, a fiber composition that makes it durable and breathable.

TEXTILES.ORG

TEXTILES.ORG