In metamaterials design, the name of the game has long been “stronger is better.” Metamaterials are synthetic materials with microscopic structures that give the overall material exceptional properties. A huge focus has been in designing metamaterials that are stronger and stiffer than their conventional counterparts. But there’s a trade-off: the stiffer a material, the less flexible it is.

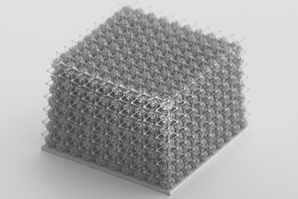

MIT engineers have now found a way to fabricate a metamaterial that is both strong and stretchy. The base material is typically highly rigid and brittle, but it is printed in precise, intricate patterns that form a structure that is both strong and flexible.

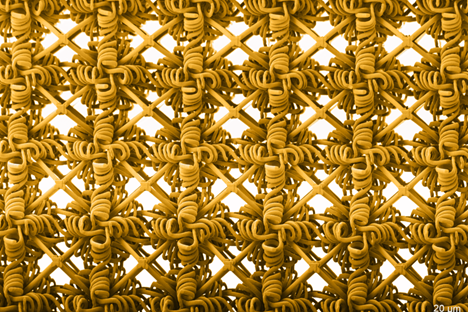

The key to the new material’s dual properties is a combination of stiff microscopic struts and a softer woven architecture. This microscopic “double network,” which is printed using a plexiglass-like polymer, produced a material that could stretch over four times its size without fully breaking. In comparison, the polymer in other forms has little to no stretch and shatters easily once cracked.

The researchers say the new double-network design can be applied to other materials, for instance to fabricate stretchy ceramics, glass, and metals. Such tough yet bendy materials could be made into tear-resistant textiles, flexible semiconductors, electronic chip packaging, and durable yet compliant scaffolds on which to grow cells for tissue repair.

“We are opening up this new territory for metamaterials,” says Carlos Portela, the Robert N. Noyce Career Development Associate Professor at MIT. “You could print a double-network metal or ceramic, and you could get a lot of these benefits, in that it would take more energy to break them, and they would be significantly more stretchable.”

Portela and his colleagues have reported their findings in the journal Nature Materials. His MIT co-authors include first author James Utama Surjadi as well as Bastien Aymon and Molly Carton.

TEXTILES.ORG

TEXTILES.ORG