On January 5, 2026, the Appropriations Committee of the U.S. House of Representatives released conference bills for important appropriations that fund federal research and allied agencies such as the National Science Foundation (NSF) and the National Institute of Standards and Technology (NIST). As of this writing, these bills are expected to pass through both houses of Congress soon so they will get enacted for full-year funding.

The Commerce, Justice, Science Act 2026 funds the National Science Foundation and will retain the FY 2026 funding close to the FY 2025 level with a slight decrease of about 3.4 percent. The President’s budget request had drastically cut the budget to this research funding engine. The outcome, although delayed, is a testament to the active involvement of stakeholders, including the public, through elected representatives and professional associations, such as the American Association for Advancement of Science and the American Chemical Society.

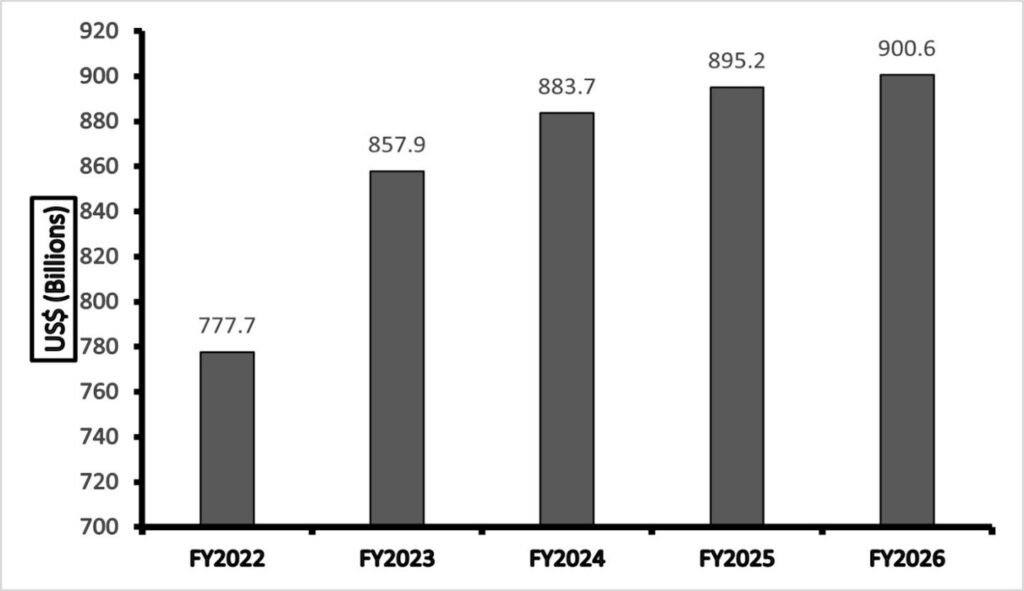

Two major appropriations that impact the materials and advanced textiles industry are the National Defense Authorization Act (NDAA), and the Commerce, Justice, Science Act (CJSA). As NDAA funds national defense and security related efforts at the Dept. of Defense (DoD) and Dept. of Energy (DOE), it gets bipartisan approval. In December 2025, the President signed the NDAA conference bill into law with a total funding for FY2026 at $900.6 billion.

The President’s budget requests for FY2026 to many departments have seen cuts including the National Institutes of Health, which would have seen a cut of about 58 percent compared to the enacted FY2025 level of $48 billion. The U.S. Congress has yet to approve the bill that would support NIH through FY2026. However, the funding request for the DoD was $892.6 billion, which when enacted reached $900.6 billion. The trend of NDAA funding levels is shown below.

Global conflicts, the need for effective border protection, and public sentiments for stronger defense favor more support for national security and homeland security efforts. Looking at the last five years of funding for defense, compared with the FY2022 enacted level, FY2026 level has increased by about 15.8 percent. While cabinet departments are expecting to get funding at last year’s (FY2025) level, the DoD got $5.4 billion more showcasing strong bipartisan support. Again, comparing the funded levels from FY2022 to FY2026, the funding level has increased each year from $777.7 billion to $900.6 billion, respectively.

Research investments and national standings

It is well understood that among other factors that have made the U.S. a superpower is its investment in research and development and contributions from highly skilled foreign nationals. It is a fact that small nations, like Israel, South Korea and Taiwan are leading nations in technology-related sectors such as defense, electronics and automobiles. Strategic investments in key high-tech sectors such as water recycling in Israel, semiconductors in Taiwan, electronics and automobiles in South Korea, have made these countries leading exporters and knowledge powerhouses in such areas.

Even though these regions witness tensions, researchers and post-doctoral scholars tend to prefer research-intensive universities such as Technion-Israel Institute of Technology, for research in specific high technology and STEM areas. Globally, in major university rankings, such as the QS and Times Higher Education (THE), research- and technology-oriented higher education institutes, such as MIT, Cambridge, Oxford, Stanford, National University of Singapore, and ETH-Zurich, occupy top ranks. In the past decade, Chinese investments in R&D have significantly increased, which is visible in its number of scientific papers and university global rankings.

Times Higher Education World University Rankings 2026 show that China has five universities in the top forty list. This list shows that United States has the highest number of top-ranked institutes, followed by India—again, the impact of investment of taxpayer dollars for R&D.

When the President Trump introduced his FY2026 budget, the scientific community was shocked to see deep funding cuts to internationally acclaimed research and funding agencies such as the National Institutes of Health and National Science Foundation. However, based on a news release from the Chair of the Appropriations Committee of the U.S. House of Representatives on January 5, 2026, funding levels for NSF would be restored.

Congress has over the years shown bipartisan support for investments in science and technology. The advanced textiles sector needs this support from the government for research, product development and evaluation. It is important that the industry continues to push for increased funding for basic research.

America first and advanced textiles

The President has said that he favors an America First agenda, which emphasizes strengthening national security, regional safety, boosting domestic manufacturing and economic security. Given this policy is aggressively pursued, efforts are underway to strengthen energy infrastructure and domestic manufacturing, as well as to secure resources in strategically important industries, such as semiconductors, medical products, biotechnology and national security.

Since COVID-19, various medical textile products have received support and national recognition. The public has become aware of the critical importance of personnel protective equipment (PPE), and the federal government has recognized that it’s crucial to have secure PPE sources.

The Trump administration has rightly initiated the Section 232 National Security Investigation on the imports of PPE, medical consumables, and medical equipment. A recommendation from the Dept. of Commerce, based on public feedback given to the President, is expected by May 2026. This exercise will highlight the weak spots in the supply chain of these life-saving products, their quality, and adherence to standards on imported products.

As soon as the investigation was initiated by the federal government in September 2025, responses from stakeholder professional associations were swift. The feedback has been in support of boosting strong domestic manufacturing as well as needing a balanced approach towards domestic manufacturing and imports. Commending the Section 232 investigation, the American Medical Manufacturers Association emphasized the need for a resilient domestic manufacturing for medical supplies and made a call for stepping up domestic manufacturing.

Looking at this aspect from the lens of an end-user community, such as the American Hospital Association, a balanced approach was emphasized. For example, in the case of PPE, a majority of items are imported; hence any policy should not be at the expense of causing supply chain disruptions. The end-user community, while insisting on the safety of patients and hence the need for stringent quality, it also highlighted the time needed to boost domestic production. Additionally, views have been expressed supporting the need for quality products at competitive prices.

Based on such feedback, the federal government must come-up with production incentives, R&D schemes, that are linked with domestic production, to boost cost-effective production in order to compete with imports. For life-saving textiles products like N95 respirators, PPEs, products that address defense, health care, and environmental protection, R&D and production-linked incentives are of prime importance.

In addition to availability and quality considerations, tariffs also play an important role in maintaining a smooth flow. There is no clear view on how the existing tariffs on Chinese imports will help with restoring the manufacturing of industrial products. In the textile sector, the area that will have growth and be competitive is the advanced textiles sector, and hence this segment needs more push in terms of policy support.

Trade and professional associations in the field such as the Association of the Nonwoven Fabrics Industry (INDA) and Advanced Textiles Association (ATA) should release reports on the supply and demand situation. as well as costing aspects. No doubt these associations are doing tremendous work in producing statistics, state of the industry and outlook. However, reports on product costs in different categories will be of great benefit to the industry to diversify, expand and invest. Particularly in the tariff era, product and product costing reports will help the industry to sustain and compete.

Talent acquisition

United States’ global standing in high-tech sectors is attributed to an industrious and highly educated workforce—and a majority of them are foreign-born. IT and biotechnology sectors hire such a workforce, who work in R&D and production primarily at supervisory levels. Shop floor workers are mostly domestic workers with vocational education or have in-house training. To stay competitive the U.S.’s industry must develop and attract next generation domestic talent as much as possible.

There is some misperception that legal and high-tech workforce immigration has replaced shop floor workforce. While this is debatable, an increase in productivity and the cost of manufacturing has shifted manufacturing to low-wage countries like China and India and hence caused a decline in manufacturing sectors. The federal government is supportive of back-shoring manufacturing, which may work in some sectors, but not in all manufacturing areas. Advanced textiles manufacturing has scope, as it is functionality based, R&D intensive, and is used in defense, health and other sensitive areas.

President Trump’s administration has a tight grip on illegal immigration. In terms of legal immigration, emphasis is based on experience, wage levels, and country-specific restrictions. According to the administration, these stringent rules are required to protect jobs for U.S. citizens. Many economists and pro-immigration organizations argue that such restriction will affect economic growth. Temporary work visas, known as H1-B, have a quota of 85,000 per year, where 20,000 has been set aside for foreign nationals who have earned a minimum of a master’s degree in the U.S. Compared to IT and biotechnology sectors, there are fewer H1-B visa applicants in the textile industry and hence changes in H1-B visa policy may not affect the industry.

The textile industry needs highly trained foreign nationals in R&D and support services such as IT. A majority of shop floor workers are a domestic workforce and retention of this workforce is an important priority for the industry. Workplace training, an encouraging wage structure, knowledge upgradation and human resources development must be carefully looked at to grow the industry.

In the advanced textiles sector, it is possible to onboard and train U.S. citizens with qualifications in technology, basic sciences, and management without heavily depending on foreign nationals, as the requirement for such a workforce is not as high as the IT sector. The industry must engage with academia that are offering engineering and management education by providing attractive internships as well as supporting research to engage talent at an early stage.

The next phase of creating interest and attracting people to the industry is to proactively engage with high school students, including an outreach effort to middle schools. Many high school students, as part of co-curricular activities, are interested in engaging in research, and hence this group of students is an important constituent for industry. Outreach with students at this level can create a pipeline for the industry to get new and energetic talent. If such efforts are structured, the industry will not be handicapped due to the unavailability of a skilled workforce.

The Nonwovens & Advanced Materials Laboratory at Texas Tech University has come up with a “Lab in a Bag,” concept to show and talk about research in advanced textiles. Using equipment that can be packed in carry bags, live demonstrations of oil absorption by a specific type of cotton are done with school students and public participants. This outreach effort has been successful and attracts high school students to engage in research, thereby creating interest among high achieving students in textiles. To the extent that industry supports outreach and engagement efforts by academia, it can be a useful strategy to attract talent.

The future is in advanced textiles

Ongoing military interventions, unsettling tariff situations, nation-first policies by many governments and changing geopolitical scenarios will be supportive for the growth of high-tech defense and allied industries. Businesses need strategic planning, diversification and capacity building to develop and manufacture products that are used in national defense and health care.

Given the new funding climate, it is not clear how support for research by small manufacturers will evolve in the federal budget. However, data show that in the case of industrial and advanced textiles sectors, investments by government via SBIR and STTR have enabled high-tech textiles such as used in space suits, life-saving responder kits, fighter plane components, parachutes, and other products. As most of these textile products fall under the radar of defense research and procurement, the funding climate will be supportive.

The government and the private sector need to focus their support on the growth of the smart textiles sector. There are several textile products that could fall into the category of smart textiles, or may have a peripheral but potentially significant relationship with smart materials, which could see growth. These are some areas which will attract government and venture capital support:

- Health monitoring textiles

- Threat-sensing defense textiles

- Multifunctional chemical products

- Non-PFAS chemistries

- Hybrid decontamination technologies

- Next-generation antiballistic materials

- High-altitude clothing, sub-zero clothing and other thermal protective apparel

- Sustainable fiber-based military clothing

- Scaled-up micro- and nano-fibrous materials

- Next-generation active space suits

- Energy-efficient filters

- Metal organic framework and graphene-based advanced textiles

In conclusion, as the world gets to be multipolar, there is competition in terms of technology might between major powers—most notably, the U.S. and China. The U.S. will likely be forced to invest in defense and advanced technologies such as modern ship building, electric vehicles, semiconductors, artificial intelligence and smart materials. As the U.S. Congress tries to wrap-up appropriation bills for the full-year funding, it is important for the industry and professional associations representing the trade, and research in these areas, to stay actively engaged with elected representatives to help with enhancing the funding for R&D and manufacturing in the next-year budget and years ahead.

Staying engaged and educating Congress and state legislatures pays off—a reason that commodity groups have been getting much needed support. Strategic planning by industry and effective communication with policymakers and the public will help with boosting policy and funding support for our industry.

Dr. Seshadri Ramkumar is a professor in the Department of Environmental Toxicology and The Institute of Environmental and Human Health, Texas Tech University, and a regular contributor to Textile Technology Source.

TEXTILES.ORG

TEXTILES.ORG