The possibility of developing a wearable fabric battery is closer to reality,due to the work of researchers at Philadelphia’s Drexel University.

The team, led by Drexel doctoral candidate Kristy Jost, is looking at threads that could turn a textile into an energy-storage device. Using a process called “natural fiber welding” (NFW), which was developed by collaborator Paul C. Trulove at the U.S. Naval Academy, Jost and her team are embedding functionalized material at the molecular level into a cellulose-based yarn, such as cotton.

Advised by Drexel Professor Yury Gogotsi and Genevieve Dion, director of the university’s Shima Seiki Haute Technology Laboratory and an assistant professor at Drexel’s Antoinette Westphal College of Media Arts & Design, Jost and her team are using NFW to strategically alter yarn for a variety of uses, but the one they’re most interested in is energy storage.

“If energy textiles are going to be realized, figuring out the best way to functionalize our yarn is the first step,” Jost told the school’s Drexel Now online newsletter. “Natural fiber welding is proving to be highly effective in producing yarns that we can tune for particular uses, including energy storage.”

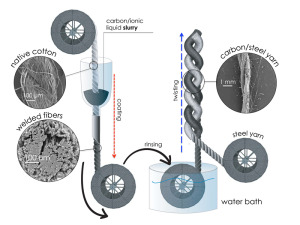

Under the process, yarn is first treated with a molten salt, which causes the polymer chains to swell, thus “opening” the structure. A functional material, such as activated carbon particles, is then embedded by sliding the yarn through a syringe filled with a mixture of the material in an ionic liquid. The yarn is then pulled through the needle of the syringe, which presses the carbon into the fibers, and it is wrapped onto a spool. The ionic liquid is removed by washing the yarn with water, which also re-solidifies the cotton fiber, trapping carbon particles in the surface.

The result is a complex, composite, fibrous material that retains its original flexibility but gains the capacitive properties of activated carbon. Much like conventional energy-storage devices (batteries) that have metal plates to improve the electrical conductivity, the activated carbon, natural fiber yarn is twisted with a highly conductive, stainless-steel yarn (the stainless steel yarn allows the material to be charged more easily).

“What’s unique about this process is that we can use any commercially available yarn made of cellulose—cotton, linen, bamboo, viscose, rayon,” Dion told the publication. “This adds another level of tunability, since we can weld thick or fine yarns, containing longer or shorter fibers, which can lead to textiles with unique mechanical properties. We use activated carbon for much of our research because it tends to be skin-friendly and is commonly found in water filters. The yarn could be embedded with a variety of carbon nanomaterials, but we’re looking ahead at making a wearable garment, so concerns like skin irritation come into play.”

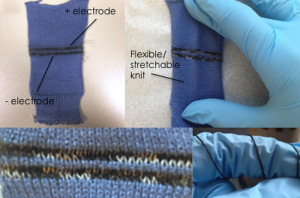

This technique for embedding carbon particles into cellulose yarn is an important step on the way to producing energy storage textiles. That development is taken even further in a paper recently published in Advanced Energy Materials in which several types of conductive yarn are tested and knit into full fabrics capable of storing energy using industrial knitting machines at the Shima Seiki Haute Technology Lab.

“This field presents more and varied challenges than just working toward improved electrochemical performance,” Jost said. “Not all new material and technique will yield electrode yarns that are suitable for knitting. Our research is unique because it looks at both the electrochemical performance and the viability of the yarn for industrial manufacturing.” Jost and her team found the best capacitance results, which were on par with conventional super-capacitors, came from the cotton yarn twisted with steel prior to welding.

“This change in the order of assembly improved the accessibility of electrons to all of the coated carbon particles because they are processed with the steel,” she said. “[That’s as] opposed to twisting them together after coating, where it was determined only about half of all the carbon was in good contact with the steel yarn. Unfortunately, despite excellent performance, none of the cotton yarns proved to knit without breaking.”

The group also tested bamboo, linen and viscose/nylon blended yarns in hopes of finding a more durable combination. None of those yarns produced the same high level of electrochemical performance as the cotton-based yarn, but all were strong enough to be knitted into a fabric without breaking.

Working with researchers at the A.J. Drexel Nanomaterials Institute, Jost and her team are developing knitted super-capacitors, while continuing to explore new material and fabrication processes.

TEXTILES.ORG

TEXTILES.ORG