IFAI’s Smart Fabrics Summit in Washington attracts a large audience of industry participants.

In addition to the presentations, the Smart Fabrics Summit held in Washington D.C. on April 24 proved to be a great way to connect with people in all areas of the smart fabrics industry. The Summit was co-sponsored by the Industrial Fabrics Association International (IFAI) and the U.S. Dept. of Commerce.

IFAI’s director of market research Jeffrey Rasmussen opened the day’s presentations with an overview of developments in the smart and interactive fabrics market – one that’s projected to grow to 3.1 billion in 2018. This represents a growth rate of 18 percent a year.

Growth, but is it enough?

While that may seem impressive, Dr. Qaizar Hassonjee, president of Hass Tech Associates LLC, says this segment of the textile industry should be growing even faster. Hassonjee and Chris Semonelli, president of Coated Technical Solutions, presented “Education and Collaboration: The Key to Moving Smart Fabrics Forward.”

“You have to work on the business part of it, not just the technology,” Hassonjee said. Many new technologies are developed by small startups, but they don’t all make it to market. The main reason startups fail is that there isn’t a market need. The solution, he says, is “Market Back Innovation,” a plan that focuses on the end-user experience, the insights and domain expertise to create the experience and, finally, the sensors/data/analytics to develop the insights. This will create a faster route to market and more value for the product, along with better profit margins.

The key to moving smart fabrics forward is to “convert everyday textiles to bring new experiences in our lives by embedding technology in textiles,” he says.

Associating with a university to accomplish some of the R&D work could help with cash flow – the second most common reason that a startup fails. This could also help to create a solid, multi-disciplinary team and avoid the third most frequent cause of failure: not having the right team.

“How are we going to feed the pipeline of workers needed to drive the smart fabrics market?” Semonelli asked. He discussed some impressive programs for students far younger than researchers at universities, where children as young as third grade are learning skills as basic as sewing and as advanced as integrating interactive capabilities into fabric products using coding and electronics.

FabNewport in Rhode Island is an innovative wearables program “where kids can go and make stuff,” he says. The point is not to teach them what they should be doing; rather, it gives children and teenagers a place to experiment for themselves. The program, funded by the Rhode Island Dept. of Education, works to present classes that don’t exist in the public schools.

Similarly, the University of Rhode Island offers the Wearable IOT Course. Students in this program have developed a variety of innovative products, including a onesie garment for newborns that integrates lighting for babies who need phototherapy, a foot massaging sock for diabetes patients, and eye glasses that monitor the sun’s UV rays.

A functional fibers pathway

MIT professor Dr. Yoel Fink, CEO of the Advanced Functional Fabrics of America (AFFOA), presented the keynote address, which outlined how AFFOA is organized and illustrated how extensive it is as a national movement. The organization has a balanced membership of 114, representing government, industry and academia.

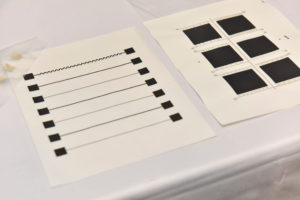

Among its developments is a startup strategy designed to speed up the process of creating, prototyping and launching new products by offering innovators a more streamlined system to create new, high-value, made-in-America products.

In developing functional fabrics, “None of us knows how to do it all. There needs to be a network of participants,” he says. “Fabrics are functional; they’re’ not ‘smart.’ People are smart.”

Fink offered some examples of new products, including LOOks™, called “the world’s first programmable backpack.” The backpack owner shares whatever information he or she chooses via a viewer’s smartphone app. “Share your story, not your identity,” says Fink. “It’s a means of self-expression, but also controls your identity.”

The backpack was developed in layers that include applications and software, a network layer, data layer and physical layer. The project has ultimately engaged nearly a dozen AFFOA member companies that could use the technology in a variety of market segments and products.

“The point is bridging the gap between what’s on the Cloud and what’s here,” he says. “Fabric can do this.”

Fiber electrification that is much more powerful than early e-textile products “will become very important in

fabrics,” he says. For one thing, fabrics will be more benign, without the means to broadcast with much power. “A solar shirt is a fraction of the impact of the smart phone you’ve carried for 10 years,” he said.

When asked about how it was possible to speed up development of new technologies, Fink pointed to the fact that AFFOA is an NDA [non-disclosure agreement] -free zone. “You need to innovate on business, too. Lawyers serve the business, not the business serves the lawyers. Paperwork slows us down; our membership agreement is one-and-a-half pages.”

He was also asked about limitations in the textile business today. “Industry is locked into a cycle. Investment in R&D and the future is really small,” he said, but added “We have some innovative manufacturers, but there are structural challenges.”

His own enthusiasm for the future possibilities was clear throughout his presentation. “You can’t come into this business without a healthy measure of optimism,” he said.

Solar structures and more

One of the success stories in innovative textiles is pvilion, a company that designs and manufactures

flexible PV solar structures and products. Although solar industrial structures may have higher up-front costs compared to more typical industrial buildings, co-founder and CEO Colin Touhey told the audience that net annual savings could cut those costs in half.

The company generally laminates their solar cells onto commercially available substrates, including for solar-powered charging stations, curtains, building facades and clothing. In the future, Touhey says solar structures are moving toward more complex designs with complex curvatures, as well. However, he says that military/defense spending will be required to make even more efficient, large, fabric solar panels.

Data security concerns

With the number and variety of products capable of connectivity growing, there are also increasing concerns about data security and privacy issues. A panel of experts addressed these issues and agreed that not building in privacy is a common mistake.

Another is that companies that offer smart fabric products are often collecting far more data than they need. The pertinent question is, “What happens to all this data?” This is of special concern in products designed for children, which would be covered by the FTC’s Children’s Online Privacy Protection Rule, said Jacqueline Connor, an attorney in the Division of Privacy and Identity Protection at the FTC. Connor called the FTC “the nation’s consumer protection agency,” and explained that it has the authority to investigate and prosecute in matters that involve smart fabrics.

New startup businesses might think they don’t have to worry about privacy issues, “but it’s not true,” said Kenya Wiley, Founder and CEO, of the Fashion Innovation Alliance, and she cautioned innovators to be careful. “There are bad actors out there.”

Julie Kearney, vice president, Regulatory Affairs, Consumer Technology Association, agreed and added “Trust is really everything in our industry.”

Janet Preus is senior editor of Advanced Textiles Source. She can be reached at jlpreus@ifai.com.

TEXTILES.ORG

TEXTILES.ORG