President Biden’s climate agenda includes support for solar energy.

by Seshadri Ramkumar

The climate change issue is front and center on today’s political stage. The massive budget bill proposed by President Biden includes a climate agenda, which has also thrown a spotlight on the subject. In fact, the passage of the bill may very well hinge on the climate deal that has sparked heated debate on opposing sides of the political spectrum in the U.S.

The recently released Solar Futures Study by the Biden administration puts a nonfossil fuel-based energy equation as the priority. Among the less conventional energy sources, solar gets high marks, as the energy policy promotes “decarbonization.”

Photovoltaics

Harvesting electrical energy from light is photovoltaics (PV) that involves using semiconductors that are polysilicon based, which are then made into panels. According to the study, the decarbonization-plus-electrification plan will deploy about 1,570 GW solar power, which will serve about 45 percent of the total U.S. energy demand in 2050. This necessitates the use of photovoltaics to satisfy the solar power need.

Photovoltaics-embedded textiles are a type of smart textile, which is a burgeoning category within the technical textiles industry. However, this subsector is nascent and is a small segment, but that offers good scope for growth and development. Market research by many consulting agencies indicate that the photovoltaics market may expect growth above 20 percent on an annual basis, and the global market size will be about $500 million by 2030.

Minding the supply chain

COVID-19 has alerted us to the need for proper pandemic planning, not only from a biomedical point of view, but also in terms of supply chain logistics issues, as developed nations are dependent on other countries for both commodity and high-tech products. The current disruptions in the supply chain point to the need for strategic planning in the manufacturing sector, including for advanced materials, such as the manufacture of solar panels and their components. Today, China leads the world in the manufacture of polysilicon based solar panels. Silicon-based semiconductor wafers have become hot commodities, as Taiwan and South Korea dominate their manufacture.

With the Biden administration’s emphasis on solar energy and advanced manufacturing, the advanced textiles sector should invest time and resources to get a foot in the door in this market area. In fact, as the foray into PV-based advanced textiles is highly research intensive, it offers scope for research universities and SMSEs to seek financial support from the government through its SBIR (Small Business Innovation Research) and STTR (Small Business Technology Transfer) programs. The huge budget spending plan proposes an investment of about $150 billion for clean electricity, which will result in fund flows for smart textiles such as infrastructure textiles and energy harvesting products.

While our familiarity with PV structures may be limited to flat panel solar cells, soft flexible fibrous structures can serve as platforms to incorporate semiconductors that harvest energy. The manufacturing process must be streamlined and bottlenecks, such as maintaining the efficiency of semiconductors incorporated in fibrous structures, must be overcome. In addition, to make such products commercially acceptable, standards must be formulated.

Manufacturing PV-based flexibles

PV-based structures are made using crystalline polysilicon which are the purest form of silicon and are highly crystalline in nature. Weaving and knitting techniques can be exploited to insert silicon wafers, which serve as platforms. The manufacturing processes must be perfected so that silicon wafers are not damaged, and their energy conversion capacities are not affected. The textile industry has perfected 3D spacer-fabric technology, which will be useful in the development of PV-based fabric structures.

Photovoltaics coatings on the flexible substrates are worth investigating. Our industry can borrow ideas from the flexible display panel sector. Flexible display screens are being made using laser crystallization of amorphous silicon without melting the substrate. As fibrous substrates are meltable and flammable depending on the type of the polymer used, efforts must be made to fully understand and choose the correct deposition techniques, such as laser or plasma vapor deposition methods.

While there are challenges in developing PV-based flexible structures, they provide opportunities for the industry and academia to engage in collaborative and multidisciplinary projects.

News in R&D

Not surprisingly, there has been much interest in the research and development of energy harvesting textiles. Professor Zhong Lin Wang’s group at Georgia Institute of Technology has been exploring triboelectric nanogenerators to harvest energy. Physical movements and light energy can be translated into electrical energy, which create enough power to charge cell phones.

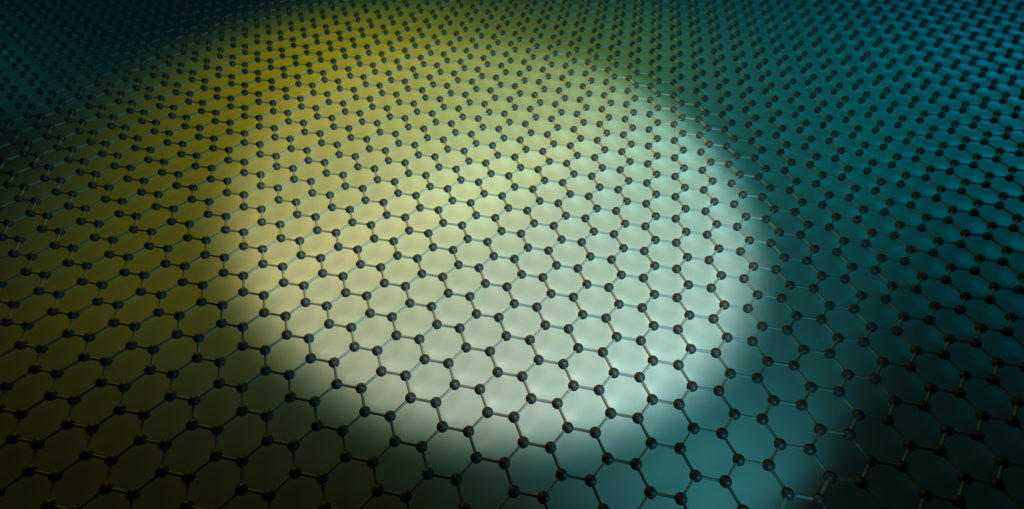

New materials have been explored that are good capacitors and conductors. Graphenes can enhance the life of batteries to store energy while remaining strong. PV-based flexible structures can harvest energy and graphene-coated structures can enhance its capacity. Such hybrid PV structures could revolutionize electric batteries.

Graphene powered batteries are already in the market, such as those from Calif.-based Real Graphene, a company that integrates graphene into affordable technology; and NanoGraf Corp., based in Illinois, which has developed a novel, high energy density Si-based anode material that the company says could replace graphitic-based anodes in lithium-ion batteries for a range of applications.

Organic polymeric materials with semiconductor properties can be bonded on to cloth materials either using coating process or using hot melt adhesives, which can harvest energy from light or from mechanical action. This development has come from the Thin-Film Device Laboratory, Riken, Japan. Conductive polymers and photovoltaic materials are used to develop fabric-based solar structures, as pioneered by scientists from Fraunhofer Institutes in Germany.

A way forward

It is clear from climate change issues that different forms of clean energy solutions must be deployed. Among the alternate forms of energy such as solar, hydro, wind and nuclear, the solar option seems most viable technically and economically. While PV-based solar panels are commercially available, flexible structures are the next phase in this field.

The technical textiles sector has the opportunity to venture into this potential field with good opportunities ahead. Immediate needs for this sector are: Large-scale translation of PV-based technologies; examining the commercial viability in terms of technical feasibility and economic acceptance; establishing reliability and safety standards.

Another fertile area to explore is to investigate hybrid technology, such graphene-based approaches. Truly multidisciplinary approaches are needed to make flexible photovoltaics commercially viable products.

Seshadri Ramkumar is a professor at Texas Tech University and a frequent contributor to Advanced Textiles Source.

TEXTILES.ORG

TEXTILES.ORG