Research and development (R&D) have a direct impact on economies worldwide. In the case of textiles, including agriculture related to textiles, it provides job opportunities to millions, including an unskilled workforce. Within the textile industry, advanced textiles and chemicals sectors place relatively more emphasis on research. The nature of the industry, size and flexibility, pressure due to competition, and the need for products that relate to health and the environment necessitate continued investment in R&D.

One issue that requiring attention by our industry is the need for additional federal funding for basic and translational research in textiles. The U. S. Dept. of Defense has been a supporter of basic and applied research in fiber and allied sectors. U.S. basic and applied research funding agencies like the National Science Foundation (NSF) and Dept. of Agriculture (USDA) need to support more projects in the fiber field.

For the industry to prioritize research areas, a basic understanding of the status and nature of federal and industrial support for R&D will be useful. Recent statistics from the Organization for Economic Cooperation and Development (OECD) showed that for 2021 the U.S. was the global leader in R&D with spending of $806 billion, followed by China at $668 billion. In 2021, EU-27 expenditures for R&D were at $ 474 billion. Japan, Germany and South Korea occupied third to fifth place, respectively.

Industry and R&D

In the U.S., a majority of federal funding goes towards development (process and product), which is a valuable support for the industry. In developed nations, the industrial contribution towards total R&D expenditures is above 50 percent. However, leading nations in the Eastern Hemisphere (Japan, China and South Korea) lead industrial contributions to total R&D, which is over 75 percent.

Statistics from agencies in the U.S. and OECD indicate the need for developed nations, particularly in the Western Hemisphere, to bump up their share in R&D. Tax incentives for in-house research, support to research in higher education institutions and workforce development need to be enhanced.

A unique research support by the U. S. National Science Foundation is the Innovation Corps (I-Corps), established to translate laboratory research to marketplace using customer surveys, feedback and discovery processes. Interaction with customers is essential for transferring research to the marketplace by understanding the societal needs and consumer expectations in terms of products and cost.

The advanced textiles industry should interact with NSF I-Corps networks in their geographical region. Such industry-institute collaboration will lead to acquiring and transferring university-based technologies to commercial spaces. The I-Corps networks connect regional industry, higher education institutions, community colleges, researchers and entrepreneurs enabling speedy transfer of research ideas.

“The Chair’s Text” agreement from the recently held Intergovernmental Negotiating Committee meeting in Busan, South Korea acknowledges the need to take appropriate measures, including legislative, to prohibit or reduce the manufacture of single use or short-lived plastic products, also highlighting the need to find alternative products to synthetics.

The INC-5 meeting did not deliver a treaty, but it provided a framework to work towards a consensus. The parties to the convention recognized the concerns of plastic pollution and at the same time noted the importance of plastics in society, emphasizing the need to establish sound protocols for plastic circularity and avoid leakages in the environment. The Chair’s Text endeavors its best to consider the interests of the plastic industry as well as those of environmentalists.

The advanced textiles sector needs such a balanced approach as the industry at present is heavily dependent on synthetics. The industry is making diligent efforts to use bio-based materials wherever applicable and promoting sustainability. The Cary N.C.-based Association of the Nonwoven Fabrics Industry (INDA) recently organized a webinar on The U.N. Global Plastics Treaty. In that event, Wes Fisher, director of government relations at INDA, said, “There is going to be enhanced demand for natural materials, and at the same time, we may not have enough supply of natural materials overnight.”

Given the international attention on plastics, circularity and alternative materials are immediate research program priorities for the technical textiles sector. The program needs to tackle a variety of aspects:

- Consensus on definition

- Alternative materials

- Full exploitation of the functionality of synthetics with fewer inputs

- Evolving effective remediation methods

- Effective education and outreach.

Bio-based materials, optimal utilization of synthetics and toxin-free chemicals, sustainable manufacturing, including chemistry formulations, are fertile areas for research related to sustainability in our industry.

Artificial intelligence

Like climate change and sustainability, which garner global attention, artificial intelligence (AI) occupies front page news, as well. The importance of basic research in the AI and machine-learning fields that translate into real world applications is evident from the number of Nobel Prizes this year on science related to AI. The conventional and the advanced textiles industry have much to gain from machine learning.

Some of the commercially successful products in the technical textiles industry are protective materials, such as awnings and shades, and weather resistant and protective clothing. There is a feeling that this field is saturated; however, industry can get ahead by understanding the weather patterns for the future and the need for different protection techniques at different geographical locations. By planning for future climate extremes, and the need for various types of clothing in different parts of world, industry can not only develop new products but also expand into new markets and locations.

Machine learning approaches based on the climate data of many years can help to extrapolate with precision and to predict the pattern in near midterm to long-term timeframes. Such an analysis of weather patterns and rainfall will help the natural fibers sector, particularly at the agronomy level, to plan and secure safety measures.

Cotton, for example, is predominantly grown as a rain-fed crop, and hence informed preparation will be valuable towards enhancing the yield. Also, such science-based forecasts will be received with confidence by policy makers and stakeholders. The volatility in the market can be controlled to some extent as the future yield prediction variations can be controlled.

In AI utilization, the conventional textile industry is a few steps ahead of the advanced textiles sector as the fashion sector is utilizing AI and machine-learning tools to predict consumer preferences and design needs for future seasons ahead.

Industry associations like the Advanced Textiles Association (ATA), The Synthetic Yarn and Fabric Association (SYFA), INDA, and the European Disposables and Nonwovens Association (EDANA), should actively engage in education and outreach efforts in AI and its applications in the textiles sector.

Multidisciplinary approaches

The next phase of research and development will be multidisciplinary. The textile industry is an ideal candidate for lending itself to science, engineering, agronomy, economics and marketing.

Chemistry and biology are predominant scientific disciplines that help with synthesizing bio-based materials including biosynthetics. In addition to synthesis, interaction with mechanical manufacturing helps with scaling-up, enabling commercial success. Researchers at the Fiber & Biopolymer Research Institute at Texas Tech University have a technology to synthesize bioplastics from waste cotton. According to researchers, bioplastics leave a smaller carbon footprint and degrade quickly. This technology enables biofilms that can find applications in sustainable packaging.

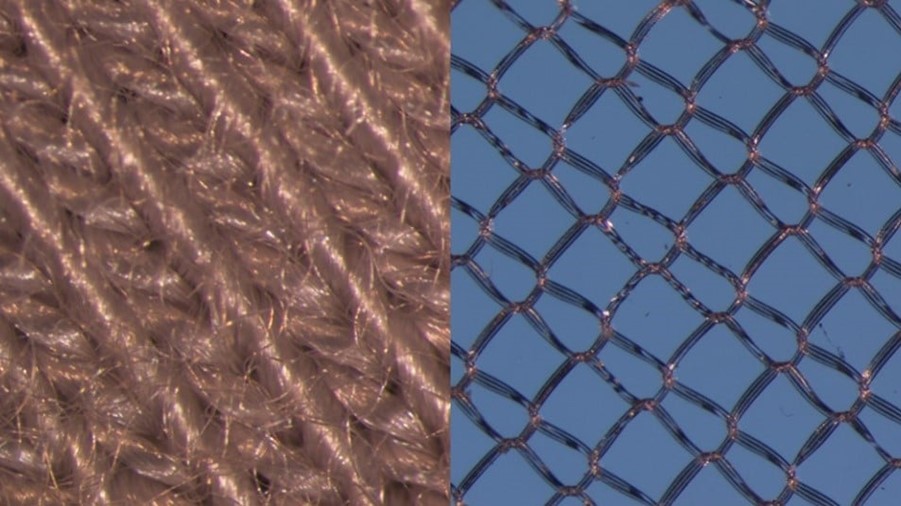

The Nonwovens Institute at NCSU is developing several nonwoven technologies to improve functionality such as fibrillation of spunmelt fabrics using mechanical methods like needlepunching and hydroentangling to improve filtration efficiencies. Researchers at Texas Tech University are utilizing design aspects to develop comfortable and efficient filters.

Defense opportunities

There are immediate opportunities for incremental research and new product development in military, medical and protective textiles; however, the U.S. edge in advanced materials can be maintained only with investments that can result in breakthrough and disruptive technologies. Such investments can happen only if the end-users and manufacturing community represented by trade associations work collaboratively.

In the technical textiles field, ATA, National Council of Textile Organizations (NCTO), and INDA support domestic manufacturing for uninterrupted supply chains. After the passage of FY-2025 National Defense Authorization Act by the U.S. House of Representatives, organizations like NCTO endorsed the passage as the Berry Amendment helps with strengthening defense procurement of quality products without supply chain interruptions.

Given the developing situation in Syria and conflicts elsewhere in the Middle East and Eastern Europe, it is evident that incremental developments are not enough. Investments in research and manufacturing to develop high performance products that have multiple functionalities are needed. The next phase of research should focus on a “Systems of Systems” approach. One such example is developing lightweight systems that give multifunctionality, such as chem-bio protection and impact resistance. As these are two different functionalities, a systems approach will be useful.

In a recent webinar, Matt O’Sickey, dirrector of educational & technical affairs at INDA, highlighted that while there is an increase in volume of nonwovens, showing an increase in consumption, materials are becoming lighter weight.

Emerging opportunities

Like the plastic and automotive sectors, the textile industry is working to improve the efficiency and cost effectiveness of circularity and recyclability. The industry must work with standardizing agencies such as ASTM and AATCC to categorize biodegradability, including industrial biodegradation, as identifying products based on degradation will create new markets and increase market acceptability.

As the advanced textiles industry needs functional chemicals and fibers, understanding their end-of-life properties, compostability and degradation will be useful. Going forward there will be demand for functional biodegradable products. The advanced textiles industry should also focus on lightweight materials as a way of controlling cost, CO2 emissions and pollution issues. The need for research is being realized by the public. There continues to be a measurable a growth trend in R&D investments in the U.S.

Dr. Seshadri Ramkumar is a professor in the Department of Environmental Toxicology and The Institute of Environmental and Human Health, Texas Tech University, and a regular contributor to Textile Technology Source.

TEXTILES.ORG

TEXTILES.ORG